Corporate Renewable Procurement for Manufacturing

- High-temperature sterilization in food processing

- Pre-heating materials in chemical manufacturing

- Drying applications in textile production

Early adopters demonstrate 40-60% thermal efficiency gains in these specialized applications, with payback periods shrinking as installation costs continue to decline.

Wind Energy Integration for Sustainable Production

Manufacturers in wind-rich regions are discovering that on-site turbines offer more than just sustainability benefits. When paired with modern battery systems (like Tesla's Megapack), wind power provides:

- 90-95% uptime reliability

- 25% lower lifetime costs than grid power in optimal locations

- Complete immunity to utility rate fluctuations

The German manufacturer Siemens Gamesa recently achieved 78% wind-powered production at its Hull facility, proving large-scale industrial applications are viable today.

Hydropower's Role in Manufacturing Sustainability

While geographic constraints limit hydropower's universal application, manufacturers near water sources unlock unique advantages:

- 50+ year operational lifespans (versus 20-25 for solar/wind)

- 85-90% capacity factors (compared to 20-40% for other renewables)

- Natural water management benefits for production processes

The historic paper mills of New England demonstrate hydropower's enduring value, with many facilities continuously operating for over a century on water power alone.

Geothermal Energy for Specialized Manufacturing

Geothermal solutions shine in specific industrial applications where consistent high heat is paramount. Notable implementations include:

- Aluminum smelting in Iceland (90% geothermal-powered)

- Glass production in volcanic regions

- Certain pharmaceutical manufacturing processes

The Hellisheiði Power Station in Iceland proves the concept at scale, providing 300MW of continuous clean energy to industrial users. While upfront costs remain high, new enhanced geothermal systems (EGS) promise to expand viable locations by 400% in coming decades.

Bioenergy: Closing the Loop on Waste

Innovative manufacturers are transforming waste streams into energy assets through:

- Anaerobic digestion of food byproducts

- Gasification of agricultural residues

- Co-firing biomass in process heaters

A leading automotive plant in Sweden achieves 95% energy independence by converting paint sludge and production waste into syngas. However, experts caution that truly sustainable bioenergy requires rigorous lifecycle analysis to prevent unintended deforestation or food supply impacts.

Beyond Generation: Smart Efficiency Measures

The most successful manufacturers combine renewable adoption with operational efficiency:

- AI-driven predictive maintenance reduces energy waste by 12-18%

- Thermal imaging identifies insulation gaps in real-time

- Closed-loop water systems cut both consumption and heating costs

Toyota's Kaizen approach demonstrates that continuous small improvements yield 5-7% annual energy reductions without major capital investments. These measures often deliver faster returns than generation projects alone.

Integrating Renewable Energy into Manufacturing Processes

Solar: Beyond Basic Installation

The solar revolution in manufacturing extends far beyond rooftop panels. Cutting-edge applications include:

- Building-integrated photovoltaics (BIPV) in factory walls

- Solar-powered robotic assembly lines

- UV-curing systems for coatings and adhesives

First Solar's Ohio plant operates a 2.4MW solar array that powers 100% of its panel production - the ultimate example of renewable energy creating more renewable energy.

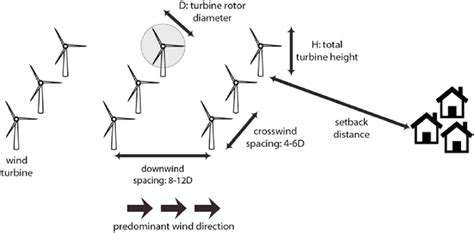

Wind: Innovation in Turbine Technology

The next generation of industrial wind solutions addresses historical limitations:

- Vertical-axis turbines for urban manufacturing sites

- Silent blade designs that meet OSHA noise requirements

- Hybrid wind-solar microgrids with 99.9% reliability

GE's new Cyclone Resistant turbines withstand 150mph winds, opening hurricane-prone regions to wind-powered manufacturing.

Water: Small-Scale Hydropower Renaissance

Modern hydro solutions don't require massive dams:

- In-pipe generators in existing water systems

- Slow-moving water turbines for canals

- Fish-friendly hydrokinetic systems

A craft brewery in Colorado generates 30% of its power from a micro-hydro system in its water intake pipeline, proving small-scale viability.

Geothermal: Breaking New Ground

Advanced geothermal technologies overcome traditional limitations:

- Low-temperature ORC systems for moderate heat needs

- Co-produced fluids from oil/gas wells

- Direct-use heating for food processing

A cheese factory in Switzerland uses 75°C geothermal water for perfect curd formation, cutting energy costs by 60%.

Modern decentralized architectures provide substantial security improvements over traditional centralized models. Information storage across multiple access points creates inherent protection against system-wide breaches, requiring potential attackers to compromise numerous independent components rather than a single vulnerable hub. This structural approach naturally enhances system durability during cyber incidents, as individual component failures don't automatically cascade into complete system outages. The transparency built into these systems enables thorough verification processes for all operations and transactions, adding another layer of security through community oversight.

Measuring What Matters: Advanced Sustainability Analytics

Next-Gen Sustainability Metrics

Leading manufacturers track beyond basic carbon metrics:

- Energy intensity per product unit

- Renewable penetration by production line

- Water-energy nexus efficiency

- Supply chain emissions scope mapping

Tesla's Gigafactory dashboard displays real-time sustainability KPIs for every workstation, driving continuous improvement.

Blockchain for Renewable Verification

Emerging technologies ensure accountability:

- Smart contracts for renewable energy purchases

- Tamper-proof production records

- Carbon credit traceability

A pilot project by BMW uses blockchain to verify that 100% of its Mexico plant's aluminum comes from solar-powered smelters.

AI-Driven Optimization

Machine learning transforms sustainability management:

- Predictive energy demand modeling

- Automated efficiency recommendations

- Dynamic renewable integration algorithms

Siemens' AI system at its Amberg facility reduces energy waste by 15% annually through real-time adjustments.