Offshore Wind Farm Layout and Design Optimization

Introduction to Offshore Wind Farm Layout Design

Site Assessment and Resource Characterization

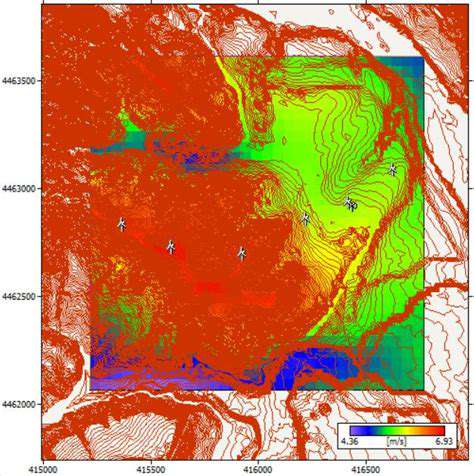

Every successful offshore wind project begins with meticulous site evaluation. Engineers must analyze wind patterns—speed, direction, and seasonal variations—across the proposed location. Precision in wind data collection directly determines turbine placement efficiency and annual energy output. Beyond atmospheric conditions, marine characteristics demand equal attention.

Wave dynamics, underwater currents, and seabed composition critically influence structural integrity. These elements dictate foundation durability and maintenance cycles. Comprehensive oceanographic surveys prevent costly design revisions during later construction phases. The collected data becomes the blueprint for all subsequent engineering decisions.

Turbine Selection and Spacing

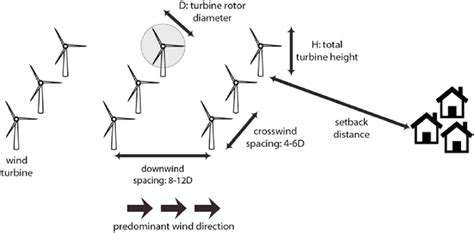

Modern wind farms employ diverse turbine models, each with unique specifications. Rotor diameter, tower height, and power curve characteristics must align with local wind profiles. Forward-thinking designs accommodate technological advancements, allowing future turbine upgrades without major layout modifications. Financial considerations balance performance aspirations with budgetary realities.

Strategic spacing addresses multiple operational challenges. Five to nine rotor diameters between units typically optimizes energy capture while minimizing wake interference. Environmental factors—particularly avian flight paths and marine mammal movements—often necessitate adjusted positioning. The final arrangement reflects compromise between energy maximization and ecological stewardship.

Cable Routing and Substation Placement

Electrical infrastructure design requires precision engineering. Subsea cables follow carefully charted routes to avoid seabed obstacles and minimize resistive losses. Double-layer armored cabling withstands harsh marine conditions while specialized burial techniques prevent damage from fishing operations. Offshore substations transform voltage efficiently, positioned centrally to reduce transmission distances.

Environmental Impact Assessment and Mitigation

Regulatory approvals hinge on comprehensive ecological studies. Seasonal wildlife monitoring identifies critical habitats requiring buffer zones. Turbine placement often incorporates migration corridors, while foundation designs may include artificial reef features to enhance marine biodiversity. Continuous underwater acoustic monitoring ensures compliance with marine mammal protection standards.

Foundation Design and Installation

Water depth and seabed composition dictate foundation choices. Monopiles dominate shallow waters (<30m), while floating platforms enable development in deeper seas. Geotechnical surveys inform pile-driving strategies, with vibro-hammer techniques reducing noise pollution. Installation vessels require precise positioning systems to achieve millimeter-level foundation placement accuracy.

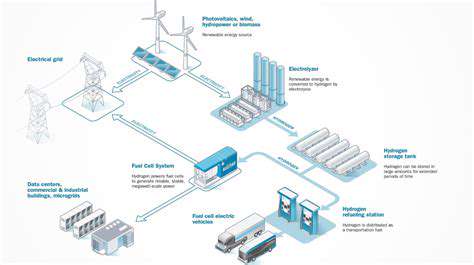

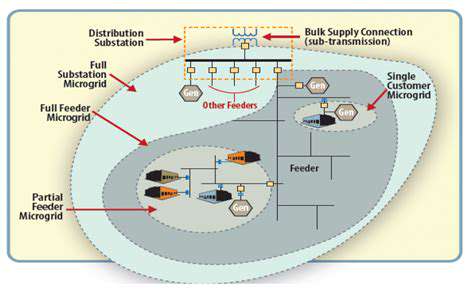

Grid Integration and Infrastructure Design

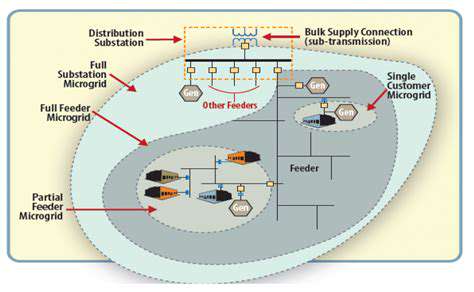

Interconnection planning begins during initial feasibility studies. Grid compatibility analyses determine necessary upgrades to onshore substations and transmission lines. Reactive power compensation systems maintain voltage stability, while advanced forecasting tools help grid operators manage intermittent generation. Some projects incorporate battery storage to smooth power delivery.

Economic Feasibility and Cost Analysis

Financial modeling considers lifecycle costs over 25-30 years. Levelized cost of energy (LCOE) calculations compare competing layout options. Maintenance logistics—including crew transfer vessel routes and helicopter access points—significantly impact operational expenditures. Risk assessments evaluate potential cost escalations from weather delays or supply chain disruptions.

Factors Influencing Wind Farm Layout Design

Site Characteristics

Topographical variations create microclimates affecting turbine performance. Mountainous terrain accelerates wind speeds through valleys while creating complex turbulence patterns. Lidar-equipped survey vessels map three-dimensional wind flows across potential sites. Bathymetric surveys identify optimal foundation locations while avoiding underwater hazards.

Environmental Considerations

Ecological constraints often reshape initial design concepts. Radar-assisted shutdown systems protect migratory birds during peak movement periods. Hydroacoustic monitoring prevents pile-driving during marine mammal breeding seasons. Visual impact assessments dictate turbine color schemes and lighting configurations to minimize shoreline visibility.

Transmission Infrastructure

Grid connection feasibility drives many siting decisions. Existing substation capacity frequently determines maximum project scale. Undersea cable corridors avoid sensitive benthic ecosystems while minimizing crossing points with shipping lanes. Some developers combine offshore wind with hydrogen production to bypass grid constraints.

Economic Factors

Financial viability depends on multiple interdependent factors. Turbine density optimization balances capital costs against energy yield. Local content requirements may influence foundation manufacturing locations. Power purchase agreement structures dictate revenue certainty, affecting financing terms and investor appetite.

Grid Integration

Modern wind farms incorporate grid-forming capabilities. Synthetic inertia systems help maintain frequency stability during generation fluctuations. Advanced power electronics enable voltage regulation without traditional synchronous generation. Some layouts reserve space for future battery storage integration as technology costs decline.

Turbine Spacing and Array Configuration

Optimizing Turbine Spacing for Maximum Efficiency

Computational fluid dynamics models simulate wake interactions under varying conditions. Staggered arrangements often outperform grid patterns in prevailing wind conditions. Sector management strategies rotate turbines to minimize wake interference during wind direction changes. Some designs incorporate vertical-axis turbines along periphery areas to capture crosswinds.

Array Configuration and Wind Resource Assessment

Multi-year wind measurements inform layout optimization. Mesoscale modeling combines historical weather data with local measurements. Machine learning algorithms process terabytes of SCADA data to identify underperforming turbine positions. Some operators implement dynamic spacing adjustments using floating foundation technologies.

Aerodynamic Interactions and Wake Effects

Wake steering strategies improve overall farm output. Individual pitch control systems redirect wakes away from downstream turbines. Thermal imaging detects turbulent flows, enabling real-time yaw adjustments. Some designs incorporate passive flow deflectors on tower structures to redirect wind streams.

Environmental Considerations and Site Characteristics

Ecological constraints shape array geometry. Marine protected areas may require non-linear turbine arrangements. Fishing exclusion zones sometimes dictate cluster configurations. Avian radar systems trigger temporary shutdowns rather than imposing blanket spacing requirements.

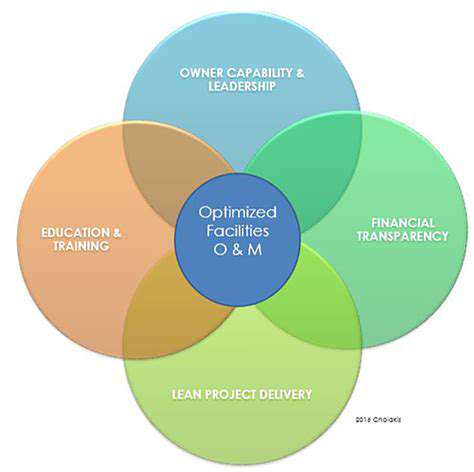

Maintenance and Access Considerations

Strategic spacing enables efficient operations. Access corridors accommodate jack-up vessels for major component replacements. Helicopter-accessible turbines feature reinforced landing pads. Some floating wind farms incorporate onboard crane systems for turbine-to-turbine transfers.

Long-Term Performance Monitoring and Optimization

Continuous data collection drives layout refinements. Digital twin technology simulates alternative configurations using real-world performance data. Annual power curve analyses identify underperforming assets. Some operators implement selective repowering—replacing specific turbines while maintaining overall array geometry.