Autonomous Wind Farm Operations: The Future of Maintenance

The Rise of AI-Powered Wind Farm Management

Optimizing Wind Turbine Performance

AI algorithms can analyze vast amounts of data from various sources, including weather patterns, turbine performance, and environmental conditions, to predict optimal wind turbine operation. This predictive capability allows for proactive adjustments in turbine settings, maximizing energy output and minimizing downtime.

By anticipating fluctuations in wind speed and direction, AI can fine-tune the turbine's angle of attack, leading to significant improvements in efficiency. This predictive maintenance capability also extends to identifying potential mechanical issues early on, preventing costly repairs and ensuring the longevity of the turbine.

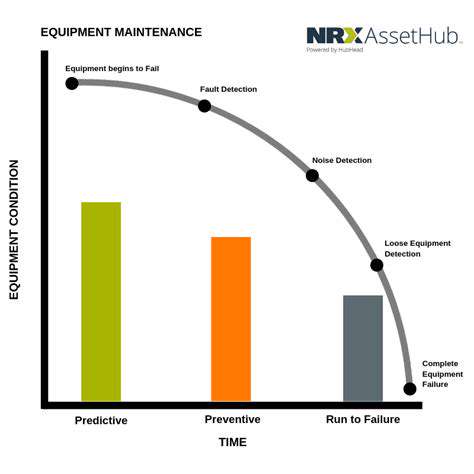

Predictive Maintenance for Enhanced Reliability

One of the most significant advantages of AI in wind farms is its ability to predict potential equipment failures. By analyzing historical data and real-time sensor readings, AI models can identify subtle patterns indicative of impending problems, allowing for proactive maintenance interventions.

This proactive approach minimizes costly downtime and ensures the consistent and reliable operation of wind turbines, resulting in a substantially higher return on investment. Predictive maintenance also enhances the overall operational safety of the wind farm by preventing unexpected breakdowns and catastrophic failures.

Improved Energy Production and Efficiency

AI-powered systems can optimize energy production by dynamically adjusting turbine settings in response to real-time wind conditions. This real-time optimization translates to improved energy output and reduced energy loss.

By leveraging machine learning, AI can adapt to changing environmental factors, ensuring peak energy generation even in unpredictable weather conditions. This enhanced efficiency translates directly to increased profitability for wind farm owners and investors.

Enhanced Safety and Operational Efficiency

AI-powered monitoring systems can significantly enhance the safety of wind farm operations by identifying potential hazards and risks in real-time. These systems can detect anomalies in turbine performance and alert operators to possible safety concerns, allowing for timely intervention to prevent accidents.

Early detection of potential hazards is crucial for minimizing risk and ensuring the safety of personnel working on or around the wind turbines. This proactive approach also contributes to the overall safety and well-being of the surrounding community by minimizing environmental impact.

Data-Driven Decision Making

The vast amount of data generated by wind turbines can be analyzed by AI to provide valuable insights into operational patterns and trends. This data-driven approach allows for informed decision-making regarding maintenance schedules, resource allocation, and overall farm management.

AI can identify areas for improvement in maintenance strategies, leading to cost savings and increased operational efficiency. The detailed analysis provided by AI can also help optimize the placement of new turbines for maximum energy capture.

Reduced Operational Costs

AI's ability to predict and prevent equipment failures translates directly into reduced operational costs. Proactive maintenance minimizes costly repairs and downtime, leading to substantial savings for wind farm operators.

Lower maintenance costs directly improve the profitability of the wind farm and enhance the long-term sustainability of the project. AI also streamlines operational processes, reducing administrative overhead and enabling more efficient use of resources.

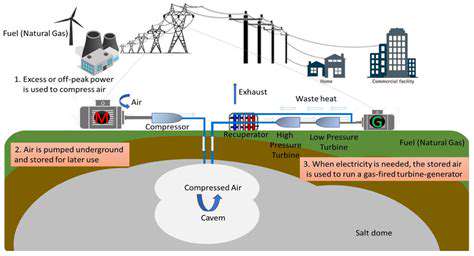

Sustainable Energy Production

AI-powered wind farms contribute to sustainable energy production by maximizing energy output and minimizing environmental impact. By optimizing turbine performance and preventing unnecessary downtime, wind farms can generate more clean energy, reducing reliance on fossil fuels.

This increased efficiency and reduced environmental footprint underscore the critical role of AI in achieving global sustainability goals. AI-driven optimization also helps to reduce the overall carbon footprint associated with energy production.

Remote Monitoring and Control for Enhanced Safety and Accessibility

Remote Monitoring Capabilities

Remote monitoring systems provide real-time visibility into critical data points, allowing for proactive identification of potential issues before they escalate. This capability is crucial for optimizing performance and minimizing downtime. The ability to track key metrics from a centralized location is a significant advantage, enabling quicker responses to emerging problems and ultimately improving overall operational efficiency.

These systems often leverage advanced sensors and data analytics to provide detailed insights into equipment performance. This data-driven approach allows for more informed decision-making, leading to optimized resource allocation and reduced operational costs.

Control Features

Remote control features empower operators to adjust settings, initiate maintenance tasks, and respond to critical events from a distance. This eliminates the need for on-site personnel in many situations, saving time and resources. This flexibility is particularly valuable in geographically dispersed environments.

Security Considerations

Robust security measures are paramount when implementing remote monitoring and control systems. Protecting sensitive data and ensuring the integrity of control systems is vital. Implementing multi-factor authentication, encryption protocols, and regular security audits are essential components of a secure remote system.

Regular vulnerability assessments and penetration testing are crucial for identifying and addressing potential security gaps. These proactive measures help to safeguard against unauthorized access and malicious activity.

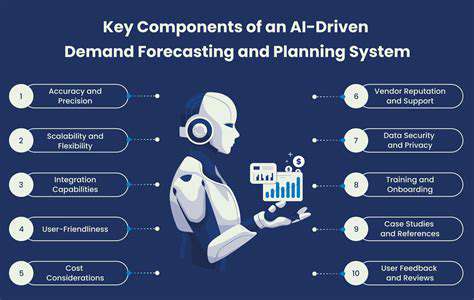

Integration with Existing Systems

Effective remote monitoring and control systems should seamlessly integrate with existing infrastructure and software. This avoids data silos and ensures a smooth transition to a more centralized management approach. A well-integrated system provides a holistic view of the entire operation, enabling a more comprehensive understanding of system performance and identifying interdependencies.

Scalability and Flexibility

The ability to scale the system to accommodate future growth and adapt to evolving needs is essential. A scalable solution allows businesses to easily adapt to changing demands and expand their remote monitoring capabilities as necessary. Modern systems should be designed with flexibility in mind, allowing for future enhancements and integrations.

Cost-Benefit Analysis

While initial investment in remote monitoring and control systems may seem substantial, the long-term benefits often outweigh the costs. Reduced downtime, optimized resource utilization, and improved operational efficiency can lead to substantial cost savings over time. These systems often provide a strong return on investment, making them a worthwhile investment for businesses seeking to enhance their operations.