Advanced Control for Wind Energy Advancements

Modern predictive control systems represent a significant leap forward in automation technology, using computational models to forecast system behavior with remarkable accuracy. Rather than waiting for errors to occur, these systems make preemptive adjustments to inputs, dramatically improving both stability and output quality. This forward-looking approach provides a clear edge over conventional reactive control methods that only respond after deviations occur.

At its core, this methodology projects future system states by analyzing current conditions and planned inputs. These projections then inform decision-making processes that optimize system performance while respecting operational boundaries and constraints.

Model-Based Approach for Precision

The effectiveness of predictive control hinges on the quality of its underlying mathematical model. This digital twin must faithfully replicate the dynamic interactions within the physical system to generate reliable forecasts. The accuracy of these models directly determines the system's ability to maintain precise control under varying conditions.

Optimization for Performance Enhancement

Advanced optimization algorithms form the backbone of predictive control systems. These computational tools continuously evaluate multiple control scenarios to identify the most efficient path that satisfies all performance requirements while minimizing resource consumption and operational costs.

Robustness to Disturbances

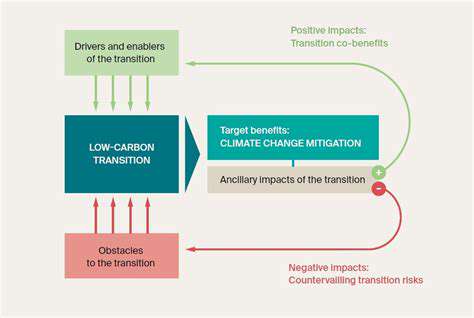

One of the most valuable characteristics of predictive control is its inherent resilience against operational disruptions. By factoring potential disturbances into its calculations during the prediction phase, the system can implement corrective measures before these disturbances significantly impact performance. This capability proves particularly valuable in industrial settings where environmental variability is inevitable.

Real-Time Implementation and Applications

The true power of predictive control emerges in dynamic environments requiring split-second adjustments. Continuous real-time processing enables these systems to respond instantaneously to changing conditions, making them ideal for applications ranging from precision manufacturing to power grid management and automated transportation systems.

Advanced Control Strategies

Modern implementations incorporate complex constraints and multi-objective optimization to handle increasingly sophisticated industrial processes. These cutting-edge approaches utilize advanced computational techniques from fields like machine learning and operations research to achieve unprecedented levels of control precision.

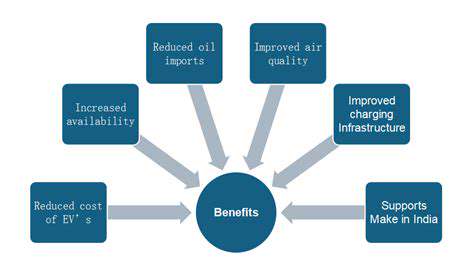

Benefits in Various Industries

The widespread adoption of predictive control across manufacturing, energy, and process industries stems from its ability to simultaneously improve quality while reducing resource consumption. By preventing operational anomalies before they occur, these systems minimize equipment wear, reduce waste, and ultimately deliver substantial economic benefits through improved operational efficiency.

Fault Detection and Diagnosis for Enhanced Reliability

Predictive Maintenance Strategies

Modern wind energy systems increasingly rely on sophisticated predictive maintenance frameworks that transform raw sensor data into actionable insights. By monitoring subtle changes in vibration patterns, thermal signatures, and electrical characteristics, these systems can identify emerging issues long before they escalate into critical failures. This proactive approach has revolutionized maintenance practices, shifting from scheduled interventions to condition-based strategies that optimize both uptime and resource allocation.

The implementation process requires careful sensor selection and advanced data processing capabilities. Modern solutions combine traditional signal processing with machine learning techniques to detect subtle anomalies that might escape conventional monitoring systems.

Advanced Diagnostic Techniques

The field continues to evolve with the introduction of multi-sensor fusion technologies that provide a more holistic view of system health. By correlating data streams from diverse sensor types, these advanced systems can compensate for the limitations of individual measurement points and improve diagnostic accuracy.

Condition monitoring has also benefited from real-time analytics that enable immediate response to abnormal conditions. These systems can detect minute deviations from normal operating parameters, allowing for early intervention that prevents minor issues from developing into major failures.

Integration with Control Systems

The most effective implementations seamlessly integrate diagnostic capabilities with control systems, creating intelligent networks that automatically adjust operations in response to developing conditions. This tight coupling enables graceful degradation rather than catastrophic failure when issues arise.

Advanced systems now incorporate adaptive control algorithms that dynamically reconfigure operational parameters based on real-time diagnostic information. This evolutionary approach represents a significant step toward autonomous industrial systems capable of self-diagnosis and self-optimization.

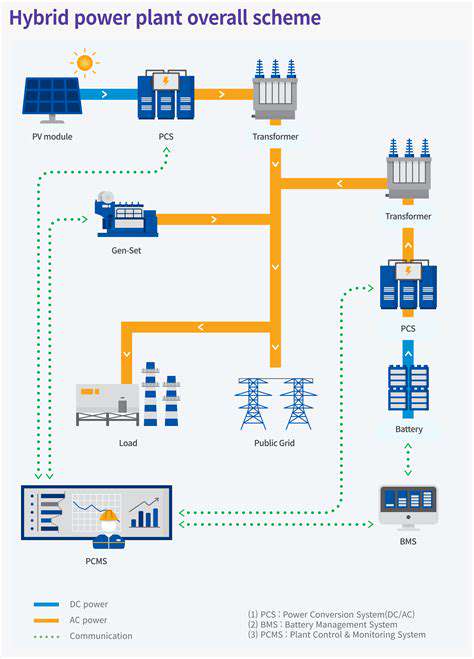

Advanced Control for Hybrid Energy Systems

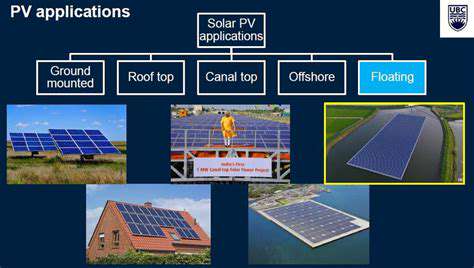

Optimizing Energy Flow

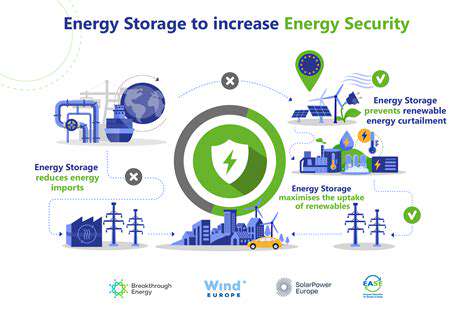

Modern hybrid systems face the complex challenge of intelligently managing energy distribution across multiple generation and storage components. The key to maximizing efficiency lies in sophisticated algorithms that make real-time decisions about energy routing based on current demand, storage status, and generation capabilities. These systems prioritize renewable sources while maintaining the flexibility to supplement from conventional sources when necessary.

Effective energy management requires continuous optimization of power flows to minimize conversion losses and maximize utilization of available resources. The most advanced implementations can predict energy needs and adjust configurations proactively rather than reactively.

Predictive Maintenance Strategies

Condition-based monitoring has become essential for maintaining the complex interplay of components in hybrid systems. By analyzing trends in performance data, these systems can schedule maintenance activities during optimal periods, avoiding unnecessary downtime while preventing unexpected failures.

The economic benefits of predictive maintenance are particularly significant for hybrid systems, where the failure of any component can disrupt the entire energy ecosystem.

Real-Time Load Balancing

Dynamic load management represents a critical capability for systems incorporating variable renewable sources. Advanced controllers continuously adjust power contributions from each available source to match instantaneous demand while respecting the operational constraints of each component.

This real-time balancing act requires sophisticated algorithms that can process multiple data streams and execute control decisions within milliseconds. The best implementations maintain seamless operation even during rapid transitions between energy sources.

Adaptive Control Algorithms

The unpredictable nature of renewable generation demands controllers that can learn and adapt to changing conditions. Modern adaptive algorithms incorporate machine learning techniques to continuously refine their models and improve decision-making over time.

This evolutionary capability allows hybrid systems to maintain optimal performance even as component characteristics change with age or environmental conditions shift unexpectedly.

Integration with Smart Grids

The future of energy management lies in the seamless integration of distributed generation with intelligent grid infrastructure. Modern hybrid systems communicate bidirectionally with grid operators, providing real-time data and responding dynamically to grid conditions.

This level of integration transforms hybrid systems from passive generators into active grid participants that can provide stability services and respond to pricing signals. The resulting ecosystem represents a fundamental shift toward more resilient and efficient energy networks.