Advanced Materials for Lighter and More Durable Wind Turbine Blades

Exploring Advanced Polymers

Polymeric materials continue evolving with remarkable versatility, offering solutions for demanding engineering applications. Recent breakthroughs in polymer science have yielded materials with unprecedented thermal stability and mechanical strength. These developments create opportunities across aerospace, automotive, and electronics sectors where performance under extreme conditions is critical.

The Rise of Metal-Organic Frameworks

Metal-organic frameworks (MOFs) represent a revolutionary class of porous materials. Their exceptionally high surface areas and tunable properties make them ideal for specialized applications. Researchers are developing MOF variants for targeted uses including environmental remediation and precision drug delivery systems.

Graphene-Based Composites: A New Frontier

Graphene's extraordinary properties are transforming material science. When integrated into composite structures, this two-dimensional material enhances strength, conductivity, and thermal performance. Industries from aerospace to consumer electronics are adopting graphene-enhanced materials to create next-generation products.

The integration of graphene into manufacturing processes is enabling lighter, stronger components with improved functionality. These advances are solving engineering challenges previously considered insurmountable.

Bio-Inspired Materials: Mimicking Nature's Design

Biomimetic materials represent a growing field that draws inspiration from natural systems. Researchers study biological structures from spider silk to abalone shells to develop synthetic materials with similar properties. These bio-inspired solutions often combine multiple desirable characteristics like self-repair mechanisms and optimized structural efficiency.

Ceramics and Advanced Ceramics: Toughness and Stability

Ceramic materials continue advancing beyond traditional applications. Modern ceramic formulations combine extreme hardness with improved fracture resistance, making them suitable for demanding mechanical and thermal environments. These materials are finding new applications in energy systems and advanced manufacturing equipment.

While sustainability certifications establish important benchmarks, their real-world implementation delivers measurable benefits. Environmentally conscious buildings consistently demonstrate superior operational efficiency, with documented reductions in energy and water consumption. These sustainable designs often achieve higher occupancy rates and property values, validating their economic advantages.

Addressing the Challenges of Material Integration

Material Selection and Compatibility

Effective material integration requires careful evaluation of multiple factors. Engineers must balance mechanical properties like tensile strength and fatigue resistance with chemical compatibility considerations. The selection process also involves assessing long-term durability under expected operating conditions while considering economic feasibility and supply chain reliability.

Manufacturing Processes for Integration

Integration techniques significantly influence final product performance. Different manufacturing approaches, from adhesive bonding to additive manufacturing, each present unique advantages. Process optimization must account for thermal and mechanical stresses to ensure structural integrity throughout the product lifecycle.

Precision manufacturing protocols can enhance material performance while reducing production defects. Factors like temperature control and pressure application require meticulous attention during fabrication.

Addressing Interface Issues

Material junctions often represent potential failure points in composite structures. Engineers employ various strategies to improve interfacial bonding, including surface treatments and transitional layers. These solutions help distribute stresses evenly across material boundaries, preventing delamination and premature failure.

Performance Characterization and Testing

Comprehensive material testing remains essential for quality assurance. Standardized mechanical tests evaluate strength and durability under simulated operating conditions. Environmental exposure testing provides critical data about long-term performance, helping predict service life and maintenance requirements.

Cost-Effectiveness and Sustainability

Material development must balance performance with economic and environmental considerations. Life cycle assessments help identify solutions that minimize ecological impact while maintaining cost competitiveness. Sustainable material choices increasingly influence purchasing decisions across industries.

Future Trends and Innovations

Emerging technologies promise to revolutionize material integration. Nanoscale engineering and smart materials represent particularly promising directions. Continued research will likely yield hybrid materials with customizable properties for specialized applications across multiple sectors.

The Future of Wind Turbine Blade Technology

Materials Innovation for Enhanced Performance

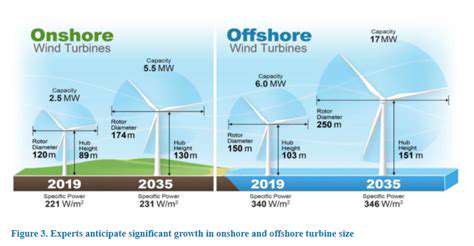

Wind energy technology continues advancing through material science breakthroughs. New composite formulations aim to reduce blade weight while increasing structural resilience. These developments could lower manufacturing costs and improve energy capture efficiency, supporting broader renewable energy adoption.

Carbon fiber technology is evolving through advanced fiber alignment techniques and novel resin systems. Incorporation of nanoscale additives enhances composite performance, enabling blades to withstand extreme operational conditions while maintaining optimal aerodynamic properties.

Advanced Manufacturing Techniques for Optimized Design

Additive manufacturing is transforming blade production processes. This technology enables complex geometries that improve aerodynamic efficiency while reducing material waste. Automated fabrication systems enhance production consistency, lowering defect rates and manufacturing costs.

Sustainability and Environmental Impact Considerations

The wind energy sector is addressing lifecycle sustainability challenges. Bio-based composite materials offer potential environmental benefits over traditional options. Simultaneously, researchers are developing efficient blade recycling methods to minimize waste and recover valuable materials.

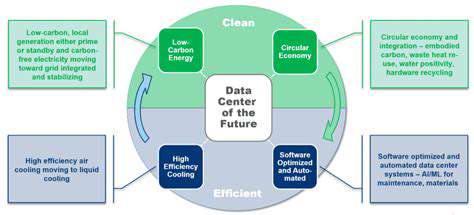

These sustainability initiatives aim to create a circular economy for wind turbine components. Such approaches align with broader environmental goals while supporting the long-term viability of wind energy infrastructure.