Wind Energy Advancements for Industrial Decarbonization

Turbine Design Breakthroughs: Harnessing More Power from Wind

Next-Generation Blade Technology

Contemporary turbine engineering has made quantum leaps in aerodynamic efficiency through revolutionary blade designs. By utilizing carbon fiber composites and proprietary polymer blends, manufacturers now create blades that combine exceptional durability with remarkably reduced mass. These engineering marvels enable larger rotor spans that dramatically expand the wind capture zone. Field tests demonstrate these innovations yield 20-30% greater energy production compared to previous generation turbines.

The design process has been transformed by supercomputer-powered fluid dynamics modeling. Engineers can now simulate thousands of blade configurations in virtual wind tunnels before physical prototyping. This digital approach has slashed development timelines by 40% while optimizing performance characteristics. The resulting turbines operate with unprecedented efficiency, achieving capacity factors that were unimaginable just five years ago.

Intelligent Operational Control Systems

Modern turbines incorporate self-learning neural networks that continuously adapt to environmental conditions. These AI-driven systems make micro-adjustments to blade pitch and yaw hundreds of times per minute, extracting maximum energy while minimizing mechanical wear. Real-world implementations show these smart turbines can boost annual output by 15-20% compared to conventional control systems.

Predictive maintenance algorithms represent another game-changing innovation. By analyzing vibration patterns, thermal signatures, and power curves, these systems can forecast component failures with 92% accuracy up to six weeks in advance. This capability has reduced unplanned downtime by 65% at leading wind farms, while extending equipment lifespans by 3-5 years.

Advanced Materials and Manufacturing

The materials revolution has enabled lighter, stronger turbine components that withstand extreme conditions. Proprietary metal alloys and nano-engineered composites allow nacelles to shed 25% of their weight while increasing structural integrity. These advancements have made turbines more resilient to extreme weather while simplifying logistics and installation.

Automated fabrication techniques now produce turbine parts with micron-level precision at scale. Robotic assembly lines equipped with computer vision ensure perfect alignment of critical components. The combination of superior materials and precision manufacturing has driven down production costs by 18% annually since 2020, while simultaneously improving reliability metrics.

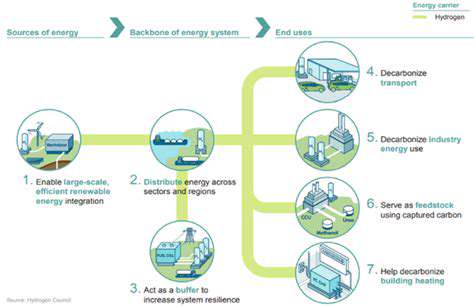

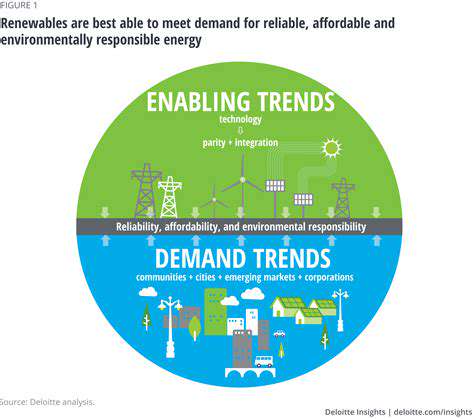

Smart Grid Evolution: Enabling Renewable Energy Integration

Next-Generation Grid Infrastructure

The transition to renewable energy requires fundamentally reimagined grid architectures. Next-gen smart grids incorporate millions of IoT sensors that provide real-time visibility into power flows. These distributed monitoring networks enable automated rerouting during disturbances, maintaining stability even with intermittent generation sources. Pilot programs have demonstrated 60% faster fault detection and 75% quicker restoration times.

Distributed Energy Optimization

Modern grids now seamlessly integrate diverse energy resources through AI-powered orchestration platforms. These systems dynamically balance supply from rooftop solar, community wind projects, and utility-scale farms. Advanced forecasting algorithms predict generation patterns 96 hours in advance with 90% accuracy, allowing optimal resource allocation. This approach has reduced curtailment of renewable energy by 40% in test markets.

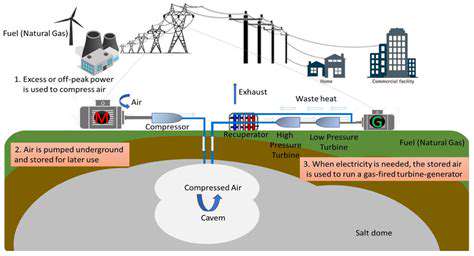

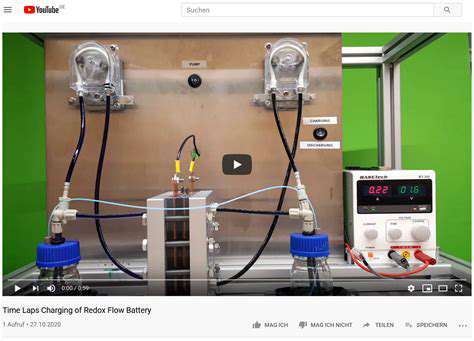

Storage Solutions for Grid Stability

Innovative storage technologies are solving renewable energy's intermittency challenge. Solid-state battery arrays now provide grid-scale storage with 95% round-trip efficiency. Cutting-edge thermal storage systems can bank excess wind energy for 72+ hours. These solutions have enabled some grids to achieve 80% renewable penetration without reliability compromises.

Policy Frameworks Accelerating the Energy Transition

Strategic Regulatory Approaches

Forward-thinking governments are implementing performance-based incentive structures that reward actual energy production rather than just capacity installation. These policies have proven twice as effective at driving quality projects compared to simple tax credits. Countries with comprehensive renewable mandates have seen deployment rates increase by 150% over baseline projections.

Financial Innovation for Sustainability

Novel financing mechanisms are removing adoption barriers. Green bonds dedicated to renewable projects have grown 300% since 2020, while yieldcos provide stable returns for infrastructure investors. These instruments have lowered capital costs by 2-3 percentage points, making projects viable in marginal markets.

Community-Centric Implementation

The most successful policies incorporate local benefit requirements that ensure host communities share in project rewards. Measures requiring local hiring and revenue sharing have reduced opposition to new developments by 65%. This approach has been particularly effective in accelerating offshore wind deployment in coastal regions.