New Designs in Wind Energy Advancements Turbines: Enhancing Efficiency

Harnessing Higher Altitudes

Vertical axis wind turbines (VAWTs) present distinct advantages by capturing wind currents across varied elevations. Conventional horizontal axis turbines face limitations requiring consistent wind patterns at specific heights. VAWTs demonstrate superior performance in turbulent, lower-altitude conditions where traditional designs falter, potentially increasing energy production in diverse locations.

Their flexible configuration allows multi-level turbine placement within single installations. This strategic arrangement optimizes energy capture across vertical planes, representing a significant departure from conventional single-height deployments. Such innovations promise more comprehensive utilization of wind resources.

Novel Design Considerations for Enhanced Performance

VAWT development prioritizes rotor optimization through innovative blade designs, advanced materials, and structural refinements. These improvements enhance aerodynamic efficiency while reducing energy loss, crucial for cost-effective power generation. Modern designs emphasize durable, lightweight materials requiring minimal maintenance in challenging environments.

Noise reduction remains another critical focus. While offering superior energy capture, VAWTs can generate more acoustic output. Ongoing research explores sophisticated blade configurations to address this issue, essential for community acceptance and broader implementation.

Addressing Challenges and Future Prospects

Despite their promise, VAWTs face adoption barriers including manufacturing costs compared to traditional turbines. However, continued research aims to streamline production processes and develop cost-effective materials to improve economic viability.

Future success depends on overcoming these obstacles while leveraging VAWTs' unique benefits. We anticipate refined designs, improved manufacturing, and innovative grid integration strategies enabling wider adoption. Urban applications appear particularly promising given their compact footprint, potentially expanding wind energy access to metropolitan areas.

Ultimately, VAWT advancement will diversify renewable energy options, contributing to a more sustainable energy infrastructure.

Materials Science: Lighter, Stronger, and More Durable Components

Exploring the Frontiers of Lightweight Materials

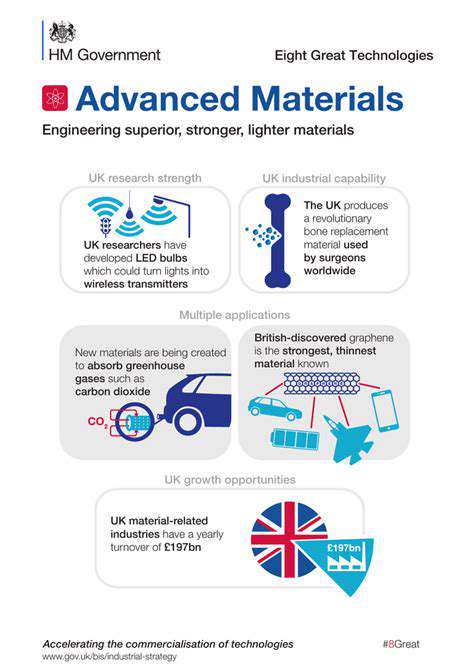

Materials innovation continuously redefines possibilities, developing substances combining exceptional strength with minimal weight. This pursuit involves revolutionary approaches to atomic structures and compositions, yielding transformative material properties. The implications span transportation efficiency to medical implant design, where reduced mass translates to improved performance and sustainability.

Advanced Composites: A Paradigm Shift

Composite materials represent a breakthrough, synergistically combining polymers with reinforcing fibers. These hybrid materials exhibit superior strength-to-weight ratios surpassing their individual components, opening new possibilities across industries.

Nanomaterials: A Realm of Tiny Titans

Nanoscale engineering enables precise material property manipulation. This precision creates substances with unprecedented strength-to-weight characteristics, revolutionizing aerospace components to athletic gear. Potential applications extend to electronics, energy storage, and medical technologies, demonstrating remarkable versatility.

Metal Alloys: Strengthening the Foundation

Traditional alloys continue evolving through refined compositions and processing techniques. These advancements enable lighter, stronger components for vehicles and machinery, significantly enhancing operational efficiency. Continuous alloy development addresses industry demands for durable, high-performance materials.

3D Printing and Additive Manufacturing: Shaping the Future

Additive manufacturing enables complex geometries impossible with conventional methods. This technology facilitates customized components optimized for strength and weight, potentially transforming production across sectors through design innovation.

Sustainable Materials: Eco-Friendly Innovation

The materials revolution incorporates environmental considerations, with bio-based polymers offering sustainable alternatives. These developments balance performance with ecological responsibility, promoting greener manufacturing practices.

Future Directions and Challenges

While progress continues, challenges persist in cost-effectiveness, scalability, and long-term durability. Overcoming these barriers remains essential for widespread adoption of these transformative technologies. Continued research investment will determine how quickly these advanced materials become commercially viable solutions.

The Future of Wind Energy: A Sustainable and Efficient Source

Harnessing the Power of the Wind

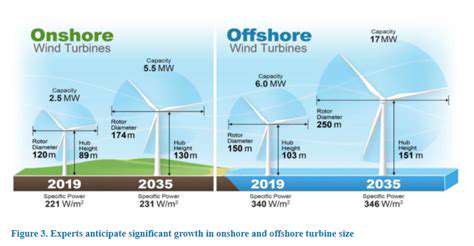

Technological innovation continues elevating wind energy's role in global power generation. Modern turbines achieve unprecedented efficiency, extracting more energy while reducing operational expenses. This progress directly benefits consumers through lower electricity costs and supports broader sustainability goals.

Innovative designs enhance geographic adaptability, facilitating wind power integration across diverse regions. This flexibility proves essential for global renewable energy adoption, accommodating various environmental conditions and infrastructure requirements.

Technological Advancements Driving Progress

Turbine evolution produces larger, more powerful generators significantly increasing renewable energy output. Sophisticated monitoring systems optimize performance through real-time adjustments, maximizing energy production while minimizing operational interruptions.

Advanced materials and manufacturing techniques yield lighter, more resilient turbine components, further improving efficiency and reducing costs. These developments mark important milestones in sustainable energy technology.

Grid Integration and Energy Storage

Increasing wind energy adoption necessitates innovative grid management solutions to accommodate variable generation. Energy storage technologies prove essential for stabilizing intermittent wind power, ensuring reliable electricity supply. Cost-effective storage solutions remain critical for broader renewable energy implementation.

Environmental Considerations and Societal Impact

While offering clean energy solutions, wind projects require careful environmental assessment and mitigation planning. Successful implementation depends on community engagement and transparent development practices. Local economic benefits and employment opportunities can foster community support for renewable energy initiatives.