Pumped Hydro Energy Storage: A Proven Technology

Types of Gravity-Based Energy Systems

Engineers have developed multiple approaches to utilize gravitational forces. Traditional hydropower systems harness falling water from elevated reservoirs, while newer concepts employ weighted systems in vertical shafts. Each configuration offers unique advantages depending on local geography and energy requirements. Some innovative designs even use abandoned mine shafts or specially constructed towers to maximize gravitational potential.

The Role of Elevation Differences

Vertical distance proves essential in these systems, with energy potential increasing proportionally to height. Modern pumped hydro facilities often seek locations with at least 300 meters of elevation change. This principle explains why mountainous regions frequently host such installations, though creative engineering can adapt the concept to various landscapes.

Challenges in Implementing Gravity-Based Systems

Construction complexities present the primary obstacle, requiring significant civil engineering works and substantial capital. Environmental permitting processes can delay projects by years, while geological surveys must ensure structural integrity. Despite these hurdles, the operational lifespan of 50-100 years makes the investment worthwhile for many communities.

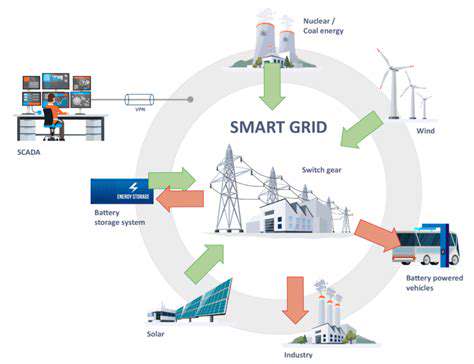

Energy Storage Capabilities

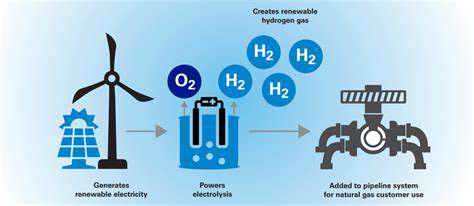

Gravity systems excel at storing surplus energy for later use, solving the intermittency issues of solar and wind generation. This storage capacity transforms renewable energy from weather-dependent to dispatchable, revolutionizing grid management. During excess production periods, energy lifts masses upward; when needed, controlled descent generates immediate power.

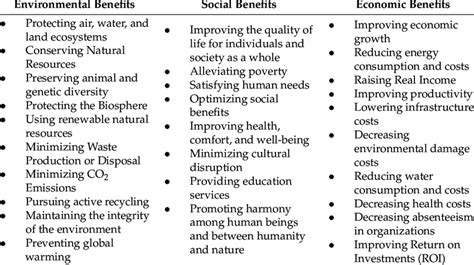

Environmental Impact and Sustainability

Compared to battery alternatives, gravity storage leaves minimal ecological footprint after construction. No toxic chemicals or rare earth metals are required for operation. The complete absence of combustion emissions makes these systems crucial for meeting carbon reduction targets. Properly designed facilities can even enhance local ecosystems through responsible water management.

Research and Development in the Field

Current innovations focus on modular designs that reduce construction timelines and costs. Advanced materials allow lighter, stronger components that improve efficiency. Researchers are particularly excited about offshore gravity storage concepts that could leverage deep ocean depths. These developments promise to make gravitational energy accessible to more regions worldwide.

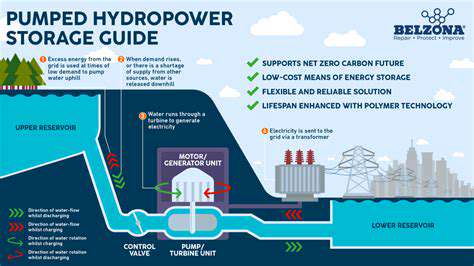

The Mechanics of Pumped Hydro Storage

Pumped Hydro Storage: The Core Concept

This century-old technology remains the most efficient large-scale energy storage method available today. During off-peak hours, surplus electricity pumps water to an upper reservoir. When demand spikes, descending water spins turbines to regenerate power. The round-trip efficiency typically exceeds 80%, outperforming most alternatives.

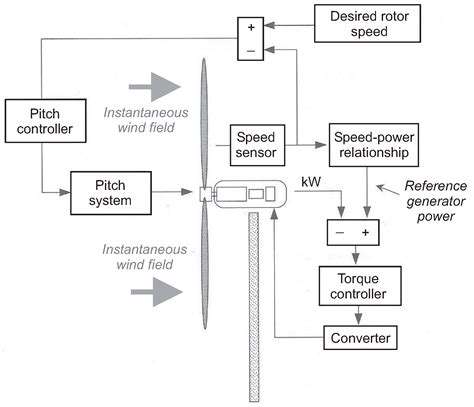

The Components of a Pumped Hydro System

Two water reservoirs at different elevations form the system's foundation, connected by penstocks and a powerhouse. The reversible pump-turbine represents an engineering marvel - functioning as both energy consumer and generator. Sophisticated control systems manage water flow with precision, while transformers connect to the electrical grid.

Pumping Process: Storing Energy

Nighttime or sunny afternoons often provide ideal conditions for charging the system. This phase converts inexpensive surplus electricity into gravitational potential energy with minimal losses. Modern variable-speed pumps optimize efficiency across different operating conditions, responding dynamically to grid needs.

Turbine Operation: Releasing Stored Energy

During morning and evening peaks, valves open to release stored water. The kinetic energy of falling water spins Francis turbines at high velocity, generating electricity within seconds of demand signals. This rapid response capability makes pumped hydro invaluable for grid stability during unexpected outages.

Efficiency and Environmental Impact

Well-designed systems achieve 70-85% round-trip efficiency, far surpassing electrochemical alternatives. The minimal energy loss makes pumped hydro economically viable despite high capital costs. While construction impacts must be carefully managed, operational emissions are negligible - a key advantage in climate-conscious markets.

Site Selection and Infrastructure

Geologists seek locations with natural elevation differences and stable geology to minimize excavation costs. Reservoir sizing requires balancing storage capacity with environmental considerations. Underground components like tunnels and surge chambers often represent the most technically challenging aspects of development.

Economic Considerations and Applications

The levelized cost of storage remains highly competitive at large scales, though financing remains challenging. Many projects utilize existing hydropower infrastructure to reduce costs. As renewable penetration increases, the value of storage capacity continues rising, improving project economics.

Advantages of Pumped Hydro Energy Storage

Increased Renewable Energy Integration

PHES acts as the perfect complement to variable wind and solar generation. By absorbing excess production and smoothing output fluctuations, it enables higher renewable penetration than would otherwise be possible. This symbiosis accelerates the transition away from fossil fuels while maintaining grid reliability.

Enhanced Grid Stability and Reliability

The inertia provided by rotating turbine masses helps stabilize grid frequency during disturbances. Operators value the millisecond response times for voltage support and black start capability. These attributes make PHES indispensable for modern power systems with high renewable shares.

Cost-Effectiveness and Economic Benefits

While upfront costs appear daunting, the 50+ year lifespan spreads expenses over decades. When accounting for cycling capability and avoided fossil fuel costs, PHES often delivers the lowest lifetime cost for bulk storage. Many systems pay back their investment within 10-15 years through energy arbitrage and ancillary services.

Reduced Reliance on Fossil Fuels

Each gigawatt of PHES capacity displaces several fossil-fueled peaking plants. This displacement effect multiplied across multiple facilities creates substantial emissions reductions. The technology thus serves as a bridge between our current energy mix and a fully renewable future.

Operational Flexibility and Scalability

From 10 MW community systems to 3 GW behemoths, PHES adapts to diverse needs. The technology scales linearly - doubling reservoir size essentially doubles storage capacity. This straightforward scalability contrasts with the complex chemistry limitations of battery systems.

Environmental Sustainability

Beyond zero operational emissions, well-designed PHES projects can improve watershed management. Some facilities incorporate fish ladders and ecological flow requirements that actually enhance local biodiversity. The long asset life also means less frequent replacement compared to other storage technologies.

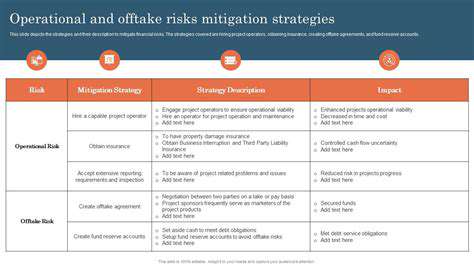

Challenges and Considerations

Navigating the Complexities of Project Management

Mega-projects demand extraordinary coordination across engineering disciplines and stakeholder groups. Successful teams employ integrated digital modeling to anticipate conflicts before construction begins. Phased development approaches help manage risk while demonstrating progress to investors.

Budgetary Constraints and Resource Management

Cost overruns remain a persistent challenge, often exceeding 30% of initial estimates. Contingency planning and value engineering help contain expenses without compromising safety or performance. Modular construction techniques are gaining popularity for reducing onsite labor requirements.

Stakeholder Engagement and Communication

Early and transparent community engagement prevents costly delays from opposition. Indigenous consultation processes often require years of relationship-building. Project teams increasingly use virtual reality simulations to help stakeholders visualize completed facilities.

Timeline Adherence and Risk Mitigation

Geotechnical surprises represent the most common schedule disruptors. Advanced ground penetrating radar and core sampling reduce - but don't eliminate - subsurface uncertainties. Contingency scheduling and parallel workstreams help maintain momentum despite unavoidable delays.

Team Dynamics and Collaboration

Large projects assemble international teams with diverse professional cultures. Cross-cultural training and clear protocols prevent misunderstandings. Regular team-building exercises maintain morale during the multi-year development process.

Quality Control and Assurance

Third-party inspection regimes verify concrete pours and welding integrity. Automated monitoring systems track thousands of quality indicators throughout construction. These measures ensure the extreme durability required for century-long operation.