Green Hydrogen for Industrial Feedstocks and High Temperature Heat

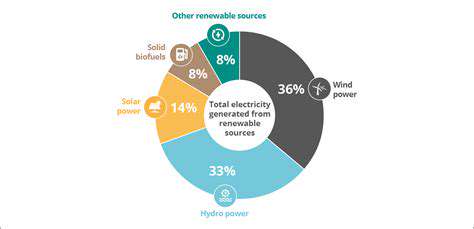

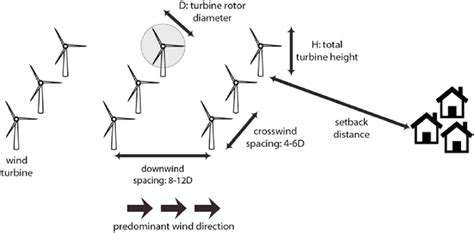

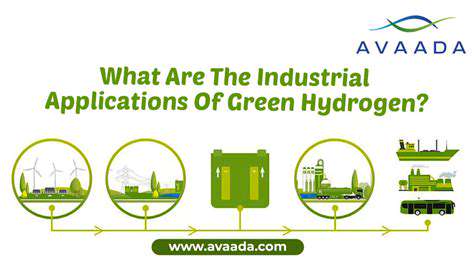

Green hydrogen, produced through electrolysis powered by renewable energy sources like solar and wind, is emerging as a crucial component of a sustainable energy future. This clean energy carrier offers a pathway to decarbonizing various sectors, including transportation, heating, and industry. Its production process, unlike traditional methods, relies on renewable energy, significantly reducing the carbon footprint associated with energy generation.

The process of electrolysis involves using electricity to split water molecules into hydrogen and oxygen. This method, when utilizing renewable energy sources, avoids the emission of greenhouse gases, making it a truly sustainable alternative to fossil fuels. This environmentally friendly approach to hydrogen production is essential to mitigating climate change.

Environmental Benefits of Green Hydrogen

The environmental benefits of green hydrogen extend beyond its production method. By replacing fossil fuels in various applications, green hydrogen significantly reduces emissions of harmful pollutants like carbon dioxide, nitrogen oxides, and particulate matter. This translates into cleaner air and improved public health, particularly in urban areas heavily reliant on fossil fuel-based transportation and industrial processes.

The reduced reliance on fossil fuels translates to a significant reduction in greenhouse gas emissions, slowing the rate of climate change. Furthermore, the transition to green hydrogen can stimulate innovation and job creation within the renewable energy sector, fostering economic growth alongside environmental sustainability.

Technological Advancements in Electrolysis

Significant advancements in electrolysis technology are driving down the cost of green hydrogen production. Innovations in membrane electrode assemblies (MEAs) and electrolyzer designs are increasing efficiency and reducing the energy required for water splitting. These improvements are crucial for making green hydrogen commercially viable and accessible to a wider range of applications.

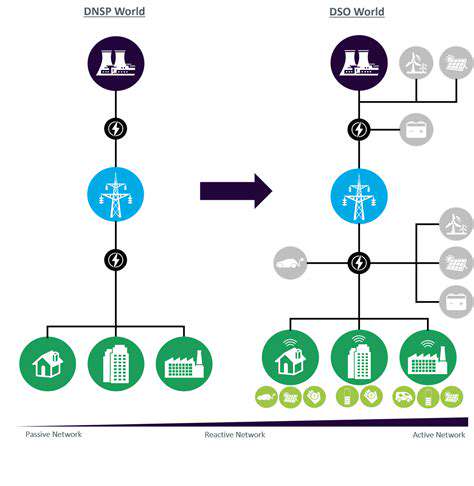

Improved electrolyzer technology is not only making the process more efficient but also increasing its scalability. This scalability is key to meeting the growing global demand for clean energy solutions and enabling large-scale deployment of green hydrogen infrastructure.

Challenges and Opportunities in Green Hydrogen Deployment

Despite the numerous advantages, challenges remain in the widespread deployment of green hydrogen. One major obstacle is the high initial investment cost associated with setting up electrolysis facilities and associated infrastructure. However, government incentives and supportive policies can help to mitigate these costs and encourage investment in the sector.

There are also opportunities for innovation and collaboration to overcome these challenges. Research and development efforts focusing on cost-effective and efficient electrolysis technologies, along with the development of optimized hydrogen storage and transportation methods, are crucial for the future success of green hydrogen.

Market Potential and Future Outlook

The market potential for green hydrogen is vast, spanning multiple sectors like transportation, heating, and industrial processes. As the cost of green hydrogen production continues to fall and the demand for sustainable energy solutions increases, the market is expected to expand rapidly in the coming years. This presents significant opportunities for investors, businesses, and governments to participate in this burgeoning industry.

The future of green hydrogen is bright, and its adoption is poised to reshape the energy landscape, leading to a cleaner and more sustainable future. Government support, technological advancements, and market demand are all converging to drive this transition.

High-Temperature Heat Applications: Powering Industrial Processes

High-Temperature Heat Transfer Mechanisms

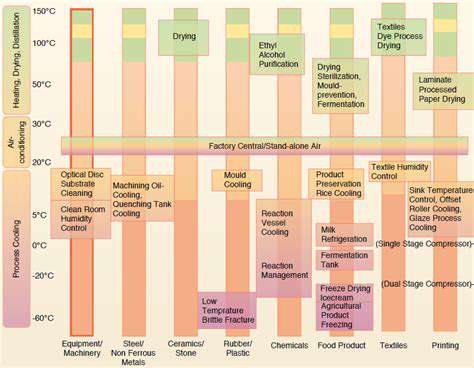

Understanding the various mechanisms of heat transfer is crucial for designing effective high-temperature systems. Conduction, convection, and radiation all play a significant role in heat transfer at elevated temperatures, and their relative importance can change depending on the specific application and material properties. For instance, in furnace designs, radiation can be a dominant mechanism, while in high-temperature fluid systems, convection becomes more prominent. A deep understanding of these mechanisms allows engineers to optimize system performance and ensure efficient heat transfer.

Material Selection for High-Temperature Environments

Choosing appropriate materials is paramount in high-temperature applications. Materials must possess exceptional thermal stability and resistance to degradation at elevated temperatures. This often necessitates the use of specialized alloys, ceramics, or composites that can withstand extreme heat without compromising structural integrity or performance. Factors like oxidation resistance, creep strength, and thermal shock resistance are critical considerations in the material selection process.

Design Considerations for High-Temperature Systems

Proper design is essential for ensuring the safety and efficiency of high-temperature systems. Careful attention must be given to thermal stress analysis, heat flux distribution, and thermal insulation to prevent overheating and maintain system integrity. A comprehensive understanding of the thermal behavior of the components is crucial for establishing a robust design that can effectively manage the high heat fluxes encountered in these applications. This also involves considering the potential for thermal expansion and contraction, which can lead to stresses and failures if not accounted for.

Safety Measures in High-Temperature Operations

Ensuring operator safety is paramount in high-temperature environments. Implementing appropriate safety protocols and protective equipment is crucial to prevent thermal burns and other injuries. Proper ventilation and monitoring of hazardous gases or byproducts are also vital safety considerations, and regular maintenance is essential to avoid unexpected failures or malfunctions. Emergency response procedures should be clearly defined and practiced to ensure a swift and effective response in case of an incident.

Applications of High-Temperature Heat in Industries

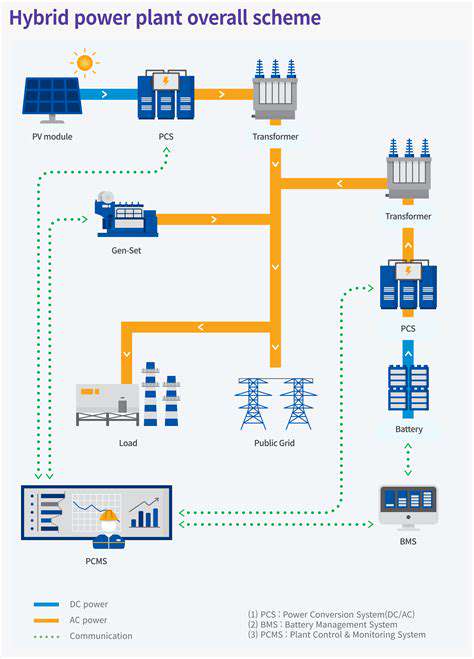

High-temperature heat applications are widespread across various industries. From power generation and metallurgy to chemical processing and aerospace engineering, these applications play a crucial role in manufacturing and energy production. The ability to generate and utilize high-temperature heat enables the production of specialized materials and fuels, and drives innovation in different industrial sectors. The demand for high-temperature heat solutions continues to grow with the increasing need for high-efficiency processes and advanced technologies.

Future Trends in High-Temperature Heat Applications

The future of high-temperature heat applications is promising, driven by advancements in materials science and engineering. Research into new materials with enhanced thermal stability and improved heat resistance is continuously pushing the boundaries of what is possible. Furthermore, advancements in thermal management systems and efficient heat transfer technologies are expected to lead to more compact and efficient high-temperature systems. These developments will contribute to the advancement of various industries and drive the development of innovative technologies.

Government policies play a crucial role in attracting private investment into renewable energy sectors. Incentives such as tax credits, subsidies, and grants can significantly lower the financial risk associated with developing and deploying renewable energy technologies. These financial mechanisms can encourage businesses to invest in research and development, construction, and operation of renewable energy projects, driving the transition to a cleaner energy future. This approach not only fosters economic growth but also helps reduce reliance on fossil fuels, mitigating climate change impacts.