Advanced Foundations for Offshore Wind: New Engineering Solutions

Redefining Offshore Wind Development Through Advanced Engineering Solutions

Navigating the Complexities of Offshore Wind Implementation

Comprehensive Site Evaluation Process

Thorough marine site evaluation forms the bedrock of effective offshore wind installations. Engineers must conduct detailed examinations of underwater terrain characteristics, studying rock formations, sediment stability, and erosion patterns. These investigations require sophisticated sonar mapping, core sampling, and predictive computer simulations to anticipate how seafloor conditions might change under operational stresses.

Marine environmental factors including tidal patterns, storm surges, and seasonal ice formations demand equal attention. These dynamic forces significantly influence structural design parameters and maintenance protocols throughout the facility's operational life.

Structural Support System Engineering

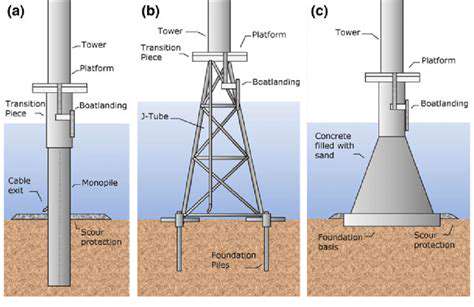

Designing underwater support structures presents unique engineering challenges that require customized solutions. Water depth variations, seabed composition, and extreme weather resistance all factor into the complex design equation. Different support configurations - from single-column designs to multi-legged frameworks - each offer distinct advantages depending on installation conditions.

The economic aspects of structural solutions cannot be overlooked. Installation expenses, ongoing upkeep costs, and environmental considerations all play into the final design selection process. The ideal solution balances structural resilience with financial practicality.

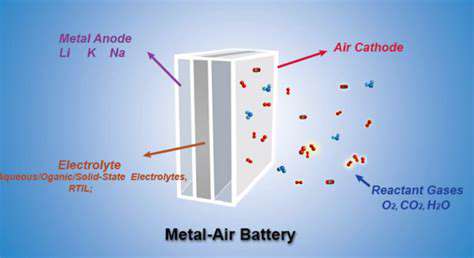

Material Science in Marine Environments

The relentless marine atmosphere demands specialized construction materials. Constant saltwater exposure, mechanical wear from ocean currents, and material fatigue from continuous stress cycles require innovative solutions. Modern metallurgical advancements have yielded corrosion-resistant alloys and protective surface treatments that dramatically extend operational lifetimes.

Material selection must also account for economic factors and supply chain considerations. The development of new composite materials continues to push the boundaries of what's possible in marine construction applications.

Deployment Logistics and Methods

Installing massive offshore structures presents formidable logistical hurdles. Specialized marine construction vessels, precision positioning systems, and advanced anchoring techniques are essential for success. The scale and complexity of these operations significantly influence project timelines and budgets.

Environmental protection measures during installation are equally critical. Careful planning minimizes disturbances to marine ecosystems while ensuring worker safety in challenging offshore conditions.

Financial Considerations and Project Economics

The financial model for offshore wind projects requires careful balancing of numerous cost factors. Installation expenses, operational budgets, maintenance forecasts, and potential government incentives all contribute to the overall economic picture. Accurate financial modeling ensures long-term project viability.

Ecological Impact Management

Responsible development mandates comprehensive environmental stewardship. Potential effects on marine habitats, aquatic species, and underwater soundscapes require thorough evaluation. Modern monitoring technologies and mitigation strategies help minimize ecological disruptions throughout the project lifecycle.

Environmental considerations extend from initial planning through eventual decommissioning, ensuring sustainable operations that coexist with marine ecosystems.

Long-Term Operational Strategies

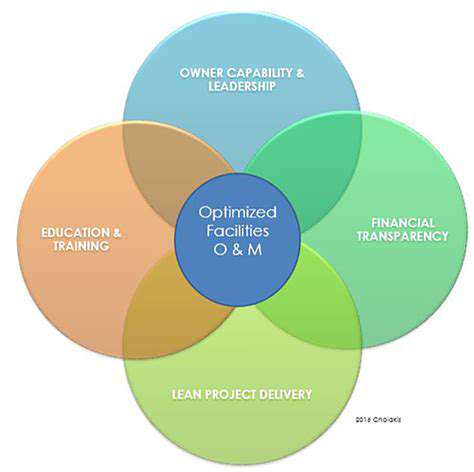

Sustainable operation requires proactive maintenance planning and eventual decommissioning protocols. Regular inspections, preventive maintenance schedules, and upgrade pathways maintain operational efficiency. End-of-life planning ensures responsible removal and material recycling when facilities reach retirement age.

Cutting-Edge Support Systems for Deepwater Applications

Modern Deep Support System Innovations

The field of deepwater structural support is experiencing rapid technological evolution. New material composites and installation techniques are revolutionizing how we approach marine construction projects. These developments offer improved performance characteristics while reducing both costs and environmental impacts.

Reinforced Marine Support Columns

Advanced composite-reinforced columns represent a significant leap forward. These utilize high-strength synthetic materials to enhance load-bearing characteristics while minimizing material requirements. The reduced physical footprint decreases installation impacts on sensitive marine environments.

Specialized Support Piling Techniques

Modern piling solutions address challenging installation scenarios where conventional methods prove inadequate. Small-diameter reinforced piles offer versatility in constrained spaces or difficult soil conditions. High-pressure injection methods create stabilized soil matrices for improved load distribution.

These advanced techniques demonstrate particular effectiveness in geologically complex marine environments where traditional approaches might fail.

Customizable Subsurface Support Structures

Site-adaptable support systems provide engineers with unprecedented design flexibility. These systems allow for precise tuning of structural parameters to match specific seabed conditions and load requirements. The ability to customize reinforcement patterns represents a major advantage over standardized solutions.

Seabed Enhancement Methods

Contemporary marine construction increasingly employs seabed modification techniques to optimize support system performance. Various compaction and stabilization methods improve load-bearing characteristics, allowing for more efficient structural designs. These integrated approaches deliver superior stability while reducing material requirements and installation complexity, particularly in challenging underwater environments.