Advanced Lithium Ion Energy Storage

Exploring Novel Materials for Enhanced Performance

Exploring Novel Carbon-Based Materials

The field of materials science has witnessed groundbreaking progress, particularly in the development of lithium-ion battery technologies. Carbon-based materials stand out as particularly promising candidates due to their exceptional electrical conductivity, expansive surface area, and adaptable porosity. These properties collectively contribute to superior battery performance. Current research focuses on diverse carbon forms, including graphene, carbon nanotubes, and porous carbons, with the goal of refining their attributes to boost lithium-ion storage capacity and accelerate charging processes. The distinctive structural features of these materials promote rapid ion movement and decrease charge transfer resistance, ultimately enhancing battery cycle life and operational efficiency.

Another critical area of investigation involves the creation of sophisticated carbon-based composites. By integrating carbon materials with elements like metal oxides or conductive polymers, scientists are achieving synergistic effects that elevate battery performance to new heights. These composite materials not only strengthen the mechanical stability of electrodes but also improve rate capabilities and increase energy density. Such innovations are vital for overcoming the constraints of conventional carbon materials and advancing lithium-ion battery technology. The prospect of developing high-performance batteries with extended lifespans and improved safety underscores the importance of this research.

Tailoring Metal Oxide Structures for Superior Performance

In addition to carbon-based solutions, the customization of metal oxide structures represents a significant frontier in lithium-ion battery enhancement. Metal oxides such as manganese dioxide (MnO₂) and cobalt oxide (CoO) serve as crucial cathode materials, and researchers are actively refining their electrochemical properties. This involves precise manipulation of nanoparticle morphology and size, careful adjustment of crystal structures, and the incorporation of dopants to improve both electronic conductivity and lithium-ion transport characteristics. These modifications can dramatically increase battery capacity, charging speed, and operational lifespan.

A fundamental component of this research focuses on the interaction between metal oxides and electrolytes. By optimizing this interface, scientists can reduce resistance and enhance overall battery efficiency. Such optimization is indispensable for achieving high energy density and ensuring stable long-term operation. The strategic engineering of these metal oxide structures holds immense potential for creating safer, longer-lasting lithium-ion batteries, thereby expanding their applications across diverse industries.

Improving Battery Safety and Durability

Enhanced Safety Mechanisms

Advanced safety protocols are essential for addressing the risks inherent in lithium-ion batteries. These protocols encompass a broad spectrum of technologies designed to prevent thermal runaway—a potentially catastrophic failure mode. State-of-the-art thermal management systems, equipped with precision sensors and rapid-response mechanisms, are central to maintaining battery safety. These systems proactively mitigate overheating risks, thereby safeguarding both the battery's integrity and its operational lifespan.

Additionally, robust battery designs incorporating cutting-edge separator materials and refined cell chemistries play a pivotal role in hazard prevention. These innovations are crucial for averting short circuits and other operational risks. The continuous evolution of these safety features represents a critical step toward more reliable and secure lithium-ion battery systems.

Advanced Materials for Superior Performance

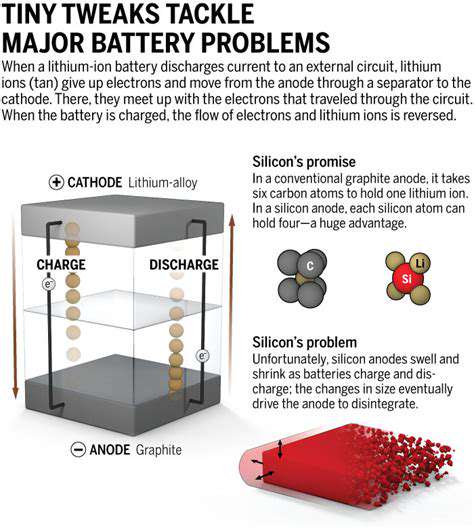

The pursuit of peak battery performance relies heavily on the adoption of innovative materials. Researchers are investigating novel electrode materials, including silicon-based anodes and nickel-rich cathodes, to achieve unprecedented energy densities and accelerated charging capabilities. These materials could revolutionize battery capacity and performance, enabling quicker recharge times and extended service life.

Equally important is the development of next-generation electrolyte materials with enhanced stability and conductivity. These advancements contribute to both safety and performance improvements, prolonging battery lifespans. Such material innovations are fundamental to meeting the demanding performance criteria of modern energy storage systems.

Optimized Battery Management Systems

Sophisticated battery management systems (BMS) are indispensable for maximizing lithium-ion battery performance and safety. Contemporary BMS technologies leverage advanced algorithms and real-time monitoring to optimize charge/discharge cycles, thereby extending battery life and preventing premature degradation.

Modern BMS solutions also incorporate intelligent thermal regulation features that maintain safe operating temperatures throughout the battery's lifecycle. These systems are vital for preserving optimal performance and preventing damage from electrical extremes. Ongoing refinement of BMS technology remains crucial for the broad adoption of advanced lithium-ion energy storage solutions.

Durability Enhancement Through Structural Design

Enhancing the structural resilience of lithium-ion battery cells is paramount for improving durability. Advanced manufacturing techniques, including precision electrode fabrication and optimized cell architecture, significantly improve resistance to mechanical stress and vibration. These improvements directly translate to extended battery lifespan.

Innovative packaging solutions and superior sealing technologies further contribute to long-term reliability by protecting battery components from environmental factors. A comprehensive approach to structural design is essential for achieving the durability demanded by contemporary energy storage applications.

Cost-Effective Production Strategies

The widespread implementation of advanced lithium-ion storage systems depends on economically viable production methods. Current efforts focus on scaling production while maintaining affordability. Innovative manufacturing processes and the utilization of readily available materials are reducing production costs, making these technologies accessible to broader markets.

The development of sustainable manufacturing protocols is equally important for minimizing the environmental impact of battery production. A balanced approach to cost-efficiency and sustainability is essential for the global adoption of advanced lithium-ion energy storage solutions across diverse applications.

Optimizing Battery Manufacturing and Scalability

Improving Cathode Material Synthesis

Refining cathode material synthesis is critical for boosting battery performance while reducing production costs. This requires meticulous control of reaction conditions—temperature, pressure, and precursor composition. Techniques like high-throughput screening and computational modeling help identify optimal synthesis parameters, yielding cathode materials with superior capacity and extended cycle life. These advancements lead to more efficient battery production and higher energy density.

Streamlining the Anode Fabrication Process

Efficient anode production is essential for scalable battery manufacturing. Methods such as electrodeposition and spray pyrolysis enable the creation of uniform, dense anode structures. Graphene-based anodes are particularly notable for their high surface area, which enhances electron transport and extends battery life. Optimizing coating and surface treatments for anode materials is equally important for minimizing side reactions and improving overall performance.

Developing Advanced Separator Technologies

Separator materials play a pivotal role in battery safety and functionality. Creating separators with superior mechanical strength and enhanced ion conductivity is essential. Advanced materials like polymer composites and ceramic-based separators can significantly boost battery performance while preventing short circuits and reducing thermal runaway risks—a major concern in lithium-ion technology.

Enhancing Electrolyte Formulation

The electrolyte's function in facilitating ion transport is fundamental to battery operation. Developing electrolytes with improved ionic conductivity and thermal stability is crucial for high-performance batteries. Advanced formulations can increase energy density, accelerate charging, and extend lifespan. This involves careful selection of solvents, additives, and ionic species to achieve the ideal balance between performance and safety.

Implementing Automation and Robotics

Automation is transforming battery production across the industry. Automated systems enhance efficiency, reduce errors, and ensure consistency in manufacturing. Robotic applications in material handling, assembly, and quality control significantly increase throughput while lowering labor costs—a critical factor in scaling production to meet the growing demands of electric vehicle markets.

Optimizing Battery Cell Assembly

Precision in battery cell assembly is crucial for large-scale production. Refining assembly processes minimizes defects and ensures consistent performance. Advanced techniques in cell stacking, sealing, and interconnection are key to achieving higher energy density and maximizing pack capacity. Efficient material utilization and space optimization during assembly are essential for streamlining manufacturing operations.

Addressing Material Sustainability and Recycling

The environmental impact of battery manufacturing is gaining increasing attention. Focusing on sustainable materials and developing effective recycling methods is essential for responsible production. Incorporating recycled materials reduces dependence on virgin resources and lessens the environmental footprint of battery manufacturing. Effective lithium-ion battery recycling is crucial for building a sustainable future and minimizing the lifecycle impact of these essential energy storage devices.

The Role of Nanotechnology in Battery Development

Nanotechnology's Impact on Materials Science

Nanotechnology is transforming materials science by enabling the creation of substances with unprecedented properties. These nanoscale-engineered materials exhibit characteristics vastly different from their bulk counterparts. This breakthrough opens new possibilities across multiple industries, from advanced electronics to medical applications. For instance, researchers are developing ultra-strong, lightweight materials for aerospace applications and innovative catalysts for environmental solutions.

The ability to manipulate materials at atomic scales allows for precise control over structure and composition. This precision yields materials with enhanced strength, conductivity, and other desirable properties—a significant leap beyond traditional trial-and-error approaches.

Applications in Electronics and Computing

Nanotechnology promises revolutionary advances in electronics miniaturization and performance. The development of nanoscale transistors and components is enabling faster, more powerful, and energy-efficient computing devices. This progress stems from the ability to integrate more components into smaller spaces, boosting processing power while reducing energy demands. Nanomaterials are also being explored for next-generation memory storage and display technologies, potentially transforming how we store and access information.

Medical Applications and Diagnostics

Nanotechnology offers transformative potential in medicine, particularly in targeted therapies and diagnostic tools. Nanoparticles can be engineered to deliver drugs directly to affected cells, minimizing side effects while maximizing treatment effectiveness. This targeted approach could revolutionize cancer treatment and other therapies.

Nanoscale sensors and imaging technologies are being developed for early disease detection and monitoring. These innovations could enable earlier diagnoses and personalized treatment plans, significantly improving patient outcomes. This represents a crucial area of research with enormous potential to advance healthcare.

Environmental Remediation and Sustainability

Nanotechnology is increasingly important in addressing environmental challenges. Nanomaterials can create highly efficient catalysts for pollution control and contaminated site remediation. Additionally, nanotechnology-enhanced materials are improving the efficiency of solar cells and other renewable energy technologies, contributing to environmental sustainability. These applications are particularly valuable as we seek solutions to climate change and sustainable development.

Nanotechnology in Energy Production and Storage

Nanomaterials are being extensively researched for energy applications, including storage and generation. Scientists are creating advanced batteries with greater capacity and faster charging using nanoscale materials. Nanotechnology also plays a vital role in developing more efficient solar cells and other renewable energy solutions. This includes novel materials that convert sunlight to electricity more effectively—innovations critical for reducing fossil fuel dependence and promoting clean energy.

Challenges and Ethical Considerations

Despite its tremendous potential, nanotechnology presents challenges that require careful consideration. Potential environmental impacts and health effects of nanomaterials need thorough evaluation. Ensuring equitable access to nanotechnology applications is equally important to prevent widening societal inequalities. Responsible development and deployment are essential for maximizing benefits while minimizing risks.

Advanced Battery Management Systems for Enhanced Performance and Safety

Improving Battery Lifespan

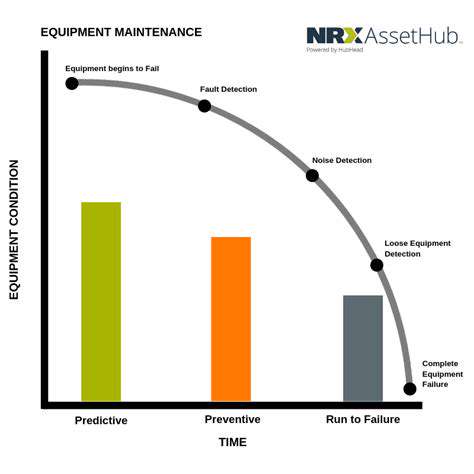

A sophisticated battery management system (BMS) is crucial for extending battery service life. Continuous monitoring and control of critical parameters—temperature, voltage, and current—prevent premature degradation and ensure optimal operation. By actively managing these factors, a BMS can significantly slow capacity fade, prolonging the battery's useful life.

Advanced BMS capabilities enable proactive intervention in potential failure scenarios. For instance, the system can detect and prevent overcharging or excessive discharge—two primary causes of battery damage. This preventive approach helps avoid irreversible capacity loss.

Optimizing Battery Performance

Beyond lifespan extension, an effective BMS enhances overall battery performance. Real-time parameter monitoring allows dynamic adjustment of charge/discharge rates, maximizing energy delivery while maintaining safe operating limits. This intelligent management results in more efficient energy use and longer intervals between charges—particularly valuable for portable devices and electric vehicles.

Comprehensive monitoring of cell-to-cell variations in voltage and temperature enables load balancing across the battery pack. This prevents uneven wear and maximizes the pack's total energy capacity. Modern BMS solutions often include predictive maintenance algorithms that identify potential issues early, allowing timely intervention and preventing failures.

The detailed operational data collected by BMS units provides valuable insights into battery health and performance trends. This information can inform operational improvements and future battery designs.

Temperature regulation is another critical BMS function. Maintaining optimal thermal conditions is essential for preventing thermal runaway—a dangerous condition that can cause rapid degradation or even fires. Effective thermal management combines sophisticated sensors with responsive control mechanisms.

Advanced BMS platforms frequently incorporate predictive maintenance algorithms. These capabilities enable early problem detection and preventive action, helping avoid costly failures in critical applications.