Solar Thermal for Industrial Process Heat: Sustainable Solutions

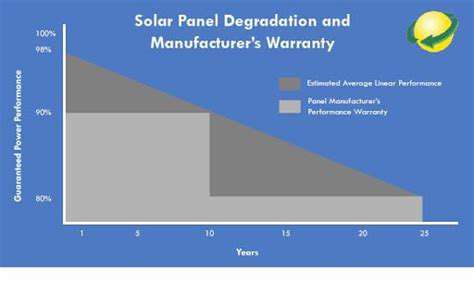

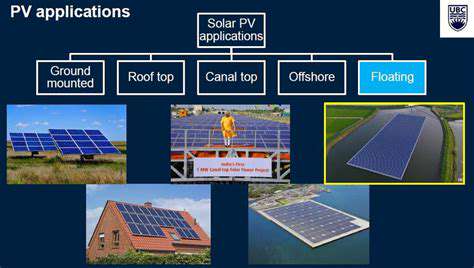

Design must align with specific energy requirements. Domestic systems differ substantially from industrial setups, while local climate and building orientation significantly influence energy capture efficiency. These factors collectively determine system effectiveness and longevity.

Applications and Benefits

Beyond residential use, solar thermal technology powers diverse industrial applications including manufacturing processes, drying operations, and sterilization. This technology dramatically reduces fossil fuel dependence, offering substantial environmental advantages.

The benefits extend beyond sustainability to include operational cost reductions, insulation from energy price volatility, and potential energy independence. These long-term economic and environmental advantages make solar thermal systems compelling investments across sectors.

Future Trends and Innovations

The solar thermal field continues evolving through ongoing research and development. Material science breakthroughs yield more efficient, durable collectors, while storage advancements enable round-the-clock energy supply. Improving efficiency while reducing costs is accelerating widespread adoption.

CSP system research focuses particularly on enhancing efficiency and lowering electricity generation expenses. These developments position solar thermal energy as increasingly competitive with traditional sources, paving the way for sustainable energy solutions.

Optimizing Solar Thermal Systems for Industrial Efficiency

Maximizing Energy Capture with Advanced Collectors

Industrial solar thermal applications depend critically on collector efficiency. Modern designs incorporate high-absorptivity, low-emissivity materials to optimize solar capture while minimizing heat loss. These innovations substantially reduce operational expenses while boosting energy output in industrial environments.

Cutting-edge materials like selective surfaces and vacuum tubes excel at concentrating and retaining solar radiation. By maximizing absorption while minimizing environmental heat transfer, these technologies significantly enhance overall system efficiency, improving cost-effectiveness and sustainability.

Optimizing System Design for Thermal Storage

Reliable thermal storage ensures consistent heat supply for continuous industrial operations, particularly crucial during non-sunlight hours. Advanced solutions like molten salts or phase change materials (PCMs) maintain thermal stability, reducing supplemental energy needs and operational interruptions.

Selecting Appropriate Fluid Types for Heat Transfer

Heat transfer fluid selection critically impacts system performance and lifespan. Industrial applications require fluids with specific properties: high thermal capacity, component compatibility, and corrosion resistance. Proper fluid selection ensures efficient heat transfer while preventing premature system degradation. Selection criteria must account for temperature ranges, pressure requirements, and environmental safety.

Integrating Control Systems for Dynamic Performance

Advanced control systems optimize performance amid fluctuating solar intensity and industrial demand variations. These automated systems adjust operations in real-time, maximizing output while minimizing energy waste. Such intelligent controls prove increasingly vital for industrial applications, enhancing both reliability and cost-efficiency.

Maintaining System Integrity and Longevity

Regular maintenance preserves system efficiency and prevents costly failures. Proactive monitoring and timely repairs for issues like leaks or corrosion extend operational lifespan. Comprehensive maintenance protocols are essential for maximizing return on investment in industrial settings.

Economic Viability and Return on Investment

Thorough economic analysis precedes solar thermal implementation. Initial costs, operational expenses, and potential savings require careful evaluation against specific industrial needs. A detailed cost-benefit analysis demonstrating projected savings and ROI proves crucial for adoption decisions.

Environmental Considerations and Sustainability

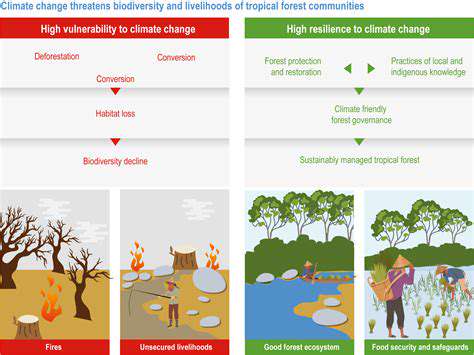

Solar thermal systems offer substantial environmental advantages over conventional energy sources. By displacing fossil fuels, they reduce greenhouse gas emissions and combat climate change. Sustainable materials and manufacturing processes further enhance their environmental profile, supporting broader adoption across industries.

The Future of Solar Thermal in Industrial Process Heating

Solar Thermal's Growing Role in Industrial Process Heating

Industrial process heating increasingly incorporates solar thermal technology as energy costs rise and sustainability concerns intensify. Improved collector technology, enhanced storage solutions, and better application understanding drive this trend. The potential for carbon footprint reduction and energy independence, combined with long-term cost benefits, fuels adoption.

Advanced Solar Collector Technologies

Collector innovations focus on maximizing energy capture, improving efficiency, and ensuring durability in demanding industrial environments. New materials and manufacturing techniques produce robust, high-performance collectors capable of continuous operation under variable conditions. CSP systems, particularly suited for high-temperature applications, represent a key development area.

Thermal Storage Solutions for Reliability

Effective thermal storage addresses solar intermittency, enabling consistent heat supply regardless of sunlight availability. Advancements in molten salt tanks and sensible heat storage systems enhance reliability for continuous industrial processes. Improving storage cost-effectiveness facilitates broader industrial adoption.

Integration with Existing Industrial Infrastructure

Successful implementation requires seamless integration with current industrial setups. Modern design approaches minimize operational disruptions while maximizing efficiency. Technological advancements increasingly simplify this integration process across diverse industrial applications.

Economic Viability and Cost-Effectiveness

While initial investments may exceed traditional methods, long-term savings and available incentives improve solar thermal's economic proposition. Operational efficiencies and reduced energy costs strengthen the financial case, particularly when considering full lifecycle costs.

Environmental Sustainability and Carbon Footprint Reduction

Solar thermal systems significantly lower industrial carbon emissions by replacing fossil fuels. This aligns with global environmental regulations and sustainability initiatives, positioning the technology as a key solution for industrial decarbonization.

Specific Applications and Case Studies

Practical applications span food processing, chemical manufacturing, and materials processing. Growing case studies demonstrate the technology's versatility and adaptability across industries, supported by ongoing application-specific research and development.