Wind Energy Advancements: Bigger, Better, Stronger Turbines

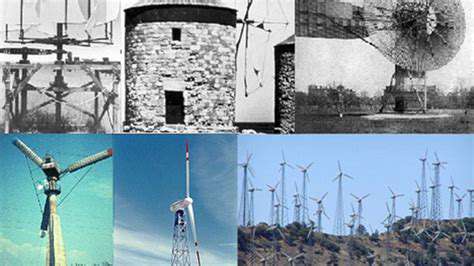

The Evolution of Wind Turbine Technology

Early Designs and Limitations

Early wind turbines, often simple vertical-axis designs, were constrained by the technological limitations of their era. These initial models faced significant challenges in efficiently harnessing wind energy and converting it into usable electricity, resulting in poor performance and inconsistent operation. Their modest output rendered them impractical for large-scale power generation. Additionally, the materials and engineering techniques available at the time led to turbines that were vulnerable to damage, shortening their operational lifespan considerably.

The Rise of Horizontal-Axis Turbines

A major breakthrough occurred with the introduction of horizontal-axis wind turbines. Featuring rotor blades aligned horizontally, these designs demonstrated superior efficiency in capturing wind energy. This configuration significantly improved the conversion of wind power into rotational force, yielding greater electricity production. Enhancements in blade aerodynamics and structural design were instrumental in boosting performance, making these turbines a practical solution for commercial energy generation.

Materials Innovation and Enhanced Durability

Progress in wind turbine technology relied heavily on the development of stronger, more resilient materials. The adoption of advanced composites and specialized alloys dramatically extended turbine lifespans while reducing maintenance requirements. These material breakthroughs enabled the construction of massive turbines capable of operating in harsh weather conditions and extreme wind environments. Such improvements were vital for expanding the operational capabilities and dependability of wind energy installations.

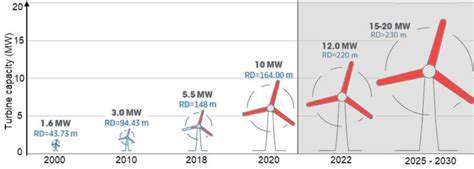

Increased Rotor Size and Capacity

Modern wind turbines feature substantially larger rotor diameters, a key factor in their improved performance. The expanded surface area allows for greater wind capture, directly increasing energy output. These enlarged turbines demonstrate dramatically enhanced generation potential. This scaling-up has been made possible by innovations in manufacturing processes, material science, and mechanical design.

Advanced Control Systems and Automation

Contemporary wind turbines incorporate sophisticated computerized control systems that optimize performance. These systems automatically adjust operations in response to shifting wind patterns, maximizing energy capture while minimizing operational interruptions. Automated diagnostic and maintenance systems significantly improve wind farm efficiency. Reduced need for manual intervention leads to lower operating costs and increased system reliability.

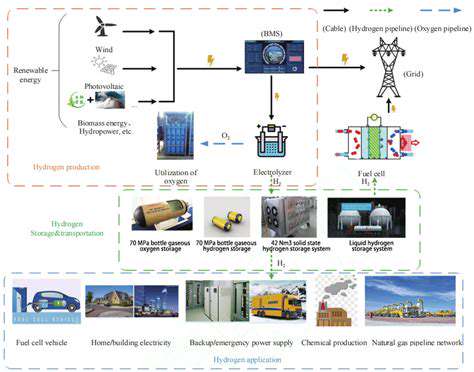

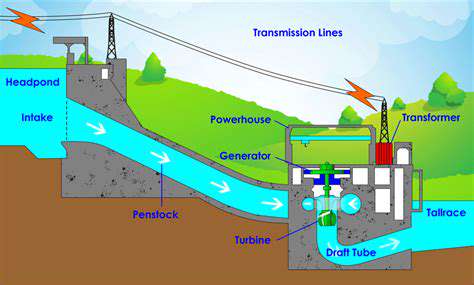

Integration with the Power Grid

Effective incorporation of wind-generated electricity into existing power networks represents a critical challenge. Modern grid interface technologies have advanced considerably, enabling reliable distribution of wind power to consumers. Sophisticated grid management systems play a crucial role in maintaining network stability and reliability. These developments have been essential for addressing the variable nature of wind energy production.

Research and Development for Future Innovations

Continuous technological innovation remains the driving force behind wind energy advancement. Scientists and engineers are investigating novel materials, innovative designs, and improved control mechanisms to enhance efficiency and reduce costs. The quest for more efficient, quieter turbine designs will be pivotal in expanding wind energy adoption. These ongoing developments position wind power as an increasingly vital and economical renewable energy source for the future.

Larger Rotor Diameters and Higher Tower Heights

Optimizing Rotor Design for Enhanced Performance

Expanded rotor dimensions, when properly engineered, can dramatically improve machinery efficiency. The greater swept area facilitates increased airflow or fluid movement, directly boosting operational output. This enhancement proves particularly beneficial in applications like turbines and compressors. Engineers must carefully evaluate the structural demands and material limitations imposed by larger rotors to ensure mechanical integrity remains uncompromised.

Additionally, scaling up rotor size often requires corresponding modifications to support structures and bearing assemblies. The relationship between rotor dimensions and supporting components is critical for maintaining stable performance and preventing vibration issues or mechanical failures. Thorough analysis and precise engineering of these interactions are fundamental to successful implementation.

Material Selection and Manufacturing Considerations

Selecting appropriate materials for oversized rotors presents significant challenges. Chosen materials must demonstrate sufficient strength, rigidity, and fatigue resistance to endure operational stresses. In many cases, high-performance alloys or composite materials become necessary to meet the demands of larger rotor applications. Environmental factors including temperature extremes, corrosive conditions, and chemical exposure must all be considered during material selection.

Fabricating large rotors frequently requires specialized production techniques. Processes like precision machining, advanced casting methods, or complex forging operations may be necessary to achieve required tolerances and material properties. These manufacturing complexities can substantially influence both production timelines and overall project costs.

Balancing and Vibration Analysis

Precision balancing represents a critical requirement for large rotating assemblies. Even minor imbalances can generate substantial vibrations, potentially causing accelerated component wear and reduced service life. Advanced balancing equipment and techniques are essential for identifying and correcting imbalance issues. Comprehensive balancing procedures are vital for ensuring optimal performance and minimal vibration.

Vibration monitoring systems provide valuable insights into rotor behavior during operation. Analyzing vibration patterns helps identify developing issues such as bearing degradation, misalignment, or material defects. Continuous vibration monitoring serves as an essential tool for predictive maintenance and failure prevention.

Impact on Efficiency and Cost

Increased rotor dimensions typically enhance system efficiency by improving fluid or gas movement. This can lead to greater output and reduced energy consumption, offering potential economic benefits over the equipment lifespan. However, the increased size and complexity of larger rotors often result in higher initial manufacturing expenses.

The additional costs associated with materials, production processes, balancing, and testing can be considerable. A thorough economic analysis is necessary to justify the investment in larger rotors, weighing potential efficiency gains against increased costs. Achieving the right balance between upfront investment and long-term benefits is crucial for decision-making.

Applications and Specific Design Considerations

Oversized rotors find application across various industrial sectors including power generation, aviation, and petroleum industries. Each application presents unique design challenges that must be addressed. Operational speeds, environmental conditions, and performance specifications must all be carefully considered during the design phase.

Different applications often require specialized design features such as customized cooling systems or enhanced bearing configurations to ensure reliable performance. Tailored engineering solutions are frequently necessary to meet the specific requirements of diverse industrial applications.

Enhanced Turbine Materials and Structures

Advanced Composite Materials

Innovative composite materials are transforming turbine engineering. These materials provide superior strength-to-weight characteristics compared to conventional metals, enabling construction of larger turbine blades with reduced mass. The decreased weight leads to lower production expenses and improved operational efficiency, enhancing the overall performance of wind energy systems.

Notable examples include carbon fiber composites and specialized metal alloys. These engineered materials are formulated to withstand the extreme stresses generated by high winds and rotational forces, extending component service life and reducing maintenance requirements. This represents a critical factor in the economic viability of wind energy projects.

Improved Blade Aerodynamics

Refined blade designs play a crucial role in maximizing energy extraction. Advanced computational modeling techniques are employed to optimize blade profiles and surface characteristics, resulting in superior aerodynamic performance. These improvements allow blades to capture more wind energy across varying wind conditions, increasing total energy production.

Aerodynamic refinements focus on reducing drag while enhancing lift characteristics. These precise design modifications contribute to more effective energy conversion from wind to electricity, resulting in higher output and reduced environmental footprint.

Robust Structural Designs

Contemporary turbine structures incorporate enhanced durability features to withstand severe weather conditions. Sophisticated engineering analysis techniques account for factors like fatigue loading and dynamic stresses to ensure structural integrity. Advanced simulation tools enable virtual testing and refinement of designs, minimizing field failure risks.

Innovative Bearing Technologies

Turbine rotor bearings must endure tremendous operational stresses. Modern bearing systems incorporate specialized lubricants and advanced materials to improve performance and longevity. Reduced friction and increased load capacity contribute to smoother operation and minimized energy losses. These improvements also decrease the frequency of bearing replacements, lowering operational expenses.

Optimized Rotor Systems

Modern rotor systems are engineered for higher rotational speeds and increased power generation. This optimization frequently involves lightweight, high-strength components and more efficient power transmission mechanisms. These technological developments result in greater generating capacity and improved wind energy harvesting efficiency.

Advanced Control Systems

Sophisticated control technologies are essential for optimal turbine operation. These systems enable real-time adjustment of blade angles and generator output in response to changing wind conditions. This dynamic responsiveness maximizes energy capture while reducing operational interruptions. Integrated sensor networks and predictive algorithms facilitate proactive maintenance, enhancing overall system reliability and performance.

Turbine Foundations and Anchoring

Improved foundation designs are critical for withstanding the substantial forces exerted on turbines during severe weather events. Innovative anchoring techniques and the use of advanced materials in foundation construction help ensure structural stability and long-term performance. These robust designs contribute to increased operational reliability and reduced vulnerability to extreme environmental conditions. Detailed geological analysis forms an essential part of the foundation design process.