The Lifecycle Assessment of Offshore Wind Energy

Material Sourcing: Ethical Considerations

Ethical sourcing is paramount in the lifecycle assessment of any product, particularly those involving materials extracted from the natural environment. This stage involves careful consideration of the environmental and social impacts of material acquisition. A thorough analysis should include the potential for deforestation, habitat destruction, and human rights violations in the supply chain. Understanding the origin and production methods of raw materials is crucial to minimizing negative externalities and promoting sustainable practices throughout the entire lifecycle.

Transparency and traceability are key elements in ethical sourcing. Companies need to be able to demonstrate the origin of materials and the conditions under which they were produced. This includes providing detailed information about suppliers, production processes, and the environmental and social impact assessments that have been conducted. Robust supply chain management systems are essential to ensure ethical and sustainable sourcing practices.

Material Sourcing: Environmental Impact

The environmental impact of material sourcing is a significant aspect of lifecycle assessment. Extracting raw materials often involves significant energy consumption, greenhouse gas emissions, and habitat destruction. The type of material sourced directly impacts its environmental footprint. For example, the extraction of rare earth minerals can contribute to land degradation and water pollution. A comprehensive lifecycle assessment must quantify these impacts throughout the extraction, processing, and transportation phases.

Sustainable alternatives to traditional materials should be evaluated. This includes exploring recycled materials, bio-based materials, and innovative technologies that reduce the environmental burden of material production. Careful analysis of the environmental impact of each potential material is essential to make informed decisions about sourcing.

Manufacturing Processes: Energy Consumption

Manufacturing processes are energy-intensive activities that significantly impact a product's environmental footprint. The amount of energy used in processing raw materials into finished products needs to be carefully quantified. This includes the energy used in extraction, refining, transportation, and the actual manufacturing operations themselves. Minimizing energy consumption at each stage is vital for reducing the overall carbon footprint.

Manufacturing Processes: Waste Generation

Waste generation during manufacturing is another critical factor in lifecycle assessment. Manufacturing processes often produce significant amounts of waste, from scrap materials to hazardous byproducts. The assessment should thoroughly evaluate the types and quantities of waste generated at each stage of the production process. Developing strategies for waste reduction, reuse, and recycling is crucial to minimizing the environmental impact of manufacturing.

Manufacturing Processes: Water Usage

Water is a vital resource in many manufacturing processes, and its usage should be carefully considered during the lifecycle assessment. The amount of water used in different production stages, from material processing to final product assembly, needs to be quantified. Water pollution from manufacturing discharge is another important consideration. Identifying and implementing water-efficient technologies and processes can significantly reduce the environmental impact of manufacturing.

Manufacturing Efficiency and Optimization

Efficiency and optimization of manufacturing processes are key factors in reducing the environmental impact of products. Identifying areas for improvement in energy consumption, waste generation, and water usage is critical. Implementing lean manufacturing principles, automation technologies, and process improvements can significantly enhance efficiency and sustainability. This includes exploring innovative manufacturing techniques that reduce material waste and improve resource utilization.

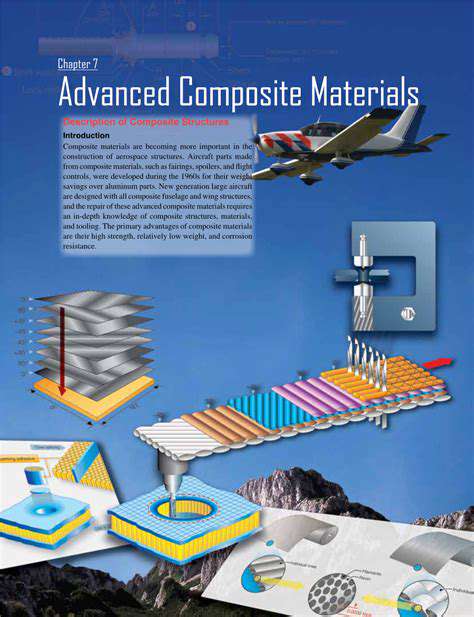

Material Selection and Substitution

The choice of materials plays a crucial role in the overall environmental performance of a product. Lifecycle assessments should consider the environmental impacts of various materials and their alternatives. Substituting traditional materials with more sustainable options can significantly reduce the environmental burden of a product. This includes exploring recycled materials, bio-based materials, and innovative materials that are less resource-intensive to produce and have a lower environmental footprint.

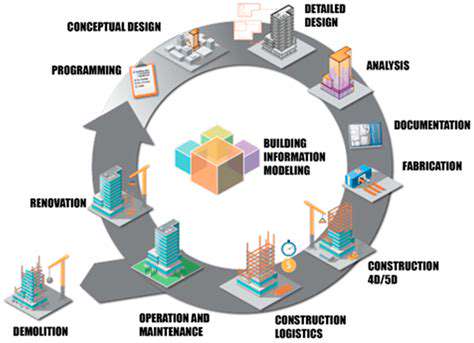

Installation and Construction: Navigating the Offshore Challenges

Planning and Site Assessment

A crucial initial step in offshore installations is thorough site assessment. This involves detailed surveys of the seabed, including geological analysis, identifying potential hazards like underwater currents, strong winds, and unstable terrain. The assessment should also consider the presence of marine life, protected areas, and any existing infrastructure in the vicinity. Accurate data collection and analysis are paramount to ensure the safety and efficiency of the entire installation process and minimize environmental impact.

Proper planning is essential for successful offshore installations. This includes developing a detailed project timeline, outlining the necessary resources (personnel, equipment, materials), and establishing clear communication channels between all stakeholders. Understanding the specific regulatory requirements and permitting procedures in the relevant jurisdiction is also critical for smooth project execution.

Foundation Design and Construction

Offshore structures require robust and resilient foundations to withstand the dynamic forces of the marine environment. Engineers must design foundations that can anchor the structure securely and prevent excessive movement or damage. This includes considering factors like wave action, tidal currents, and potential seismic activity. Advanced materials and construction techniques are often employed to create foundations capable of withstanding extreme conditions and ensuring long-term stability.

Construction of offshore foundations frequently involves specialized equipment and techniques. Precise placement and secure connections are crucial for the stability of the entire structure. Rigorous quality control measures are implemented throughout the process to guarantee the integrity and safety of the foundation.

Platform Erection and Assembly

Platform erection is a complex and demanding phase, requiring meticulous planning and precise execution. Safety protocols are paramount throughout the entire process, with strict adherence to established procedures. Specialized lifting equipment and experienced personnel are essential for the safe and efficient handling and positioning of the platform components. Careful coordination between different teams involved in the process is crucial to ensure that all elements are assembled correctly and efficiently.

Subsea Pipelines and Cables

The installation of subsea pipelines and cables is a vital aspect of offshore projects. These critical components connect the platform to onshore facilities, transporting fluids and power. The design and construction of these systems must account for the unique challenges of the marine environment, including corrosion, pressure variations, and potential damage from marine life or other vessels. Advanced materials and specialized installation techniques are utilized to ensure the integrity and durability of these critical components.

Electrical and Utility Systems

Offshore platforms rely on complex electrical and utility systems for operation and maintenance. These systems need to be designed and installed to withstand the harsh marine environment and provide reliable power and support for various operations. The design must take into consideration the potential for extreme weather conditions, sea currents, and electromagnetic interference. Extensive testing and quality control measures are implemented to ensure the performance and safety of these systems.

Environmental Considerations and Mitigation

Environmental protection is a critical aspect of offshore installations. Strict adherence to environmental regulations and best practices is essential throughout the project lifecycle. Measures to minimize the impact on marine ecosystems are implemented, including careful planning to avoid disruption of marine life, proper waste disposal, and diligent monitoring of the surrounding environment. Ongoing assessment and mitigation of potential environmental risks are crucial for long-term sustainability of offshore operations.

Haptic feedback, or the sense of touch, is often overlooked in immersive design, yet it can be a powerful tool for enhancing user engagement and creating a more holistic experience. In virtual reality or augmented reality environments, haptic devices can simulate a wide range of textures, from the smoothness of silk to the roughness of stone, allowing users to experience the environment more realistically.

Operational Phase: Optimizing Energy Production and Maintenance

Defining Operational Efficiency

The operational phase of energy management is crucial for optimizing energy consumption and ensuring efficient utilization of resources. This involves a multifaceted approach encompassing various strategies and technologies. Understanding the specific energy needs of different processes and departments is paramount to implementing targeted solutions. A thorough analysis of energy usage patterns helps to identify areas where improvements can be made, leading to a more sustainable and cost-effective operation.

Careful monitoring and evaluation of energy consumption throughout the operational process are essential for long-term optimization. This data-driven approach enables proactive identification of inefficiencies and opportunities for improvement. Regular reporting and analysis facilitate the tracking of progress and the adjustment of strategies as needed.

Implementing Energy-Saving Technologies

Integrating energy-saving technologies is a key aspect of optimizing energy usage during the operational phase. This encompasses a broad spectrum of options, from upgrading lighting systems to implementing smart building controls and optimizing HVAC systems. Implementing these technologies can significantly reduce energy consumption and lower operational costs.

Advanced technologies like smart grids and energy storage systems can further enhance efficiency and reliability. These technologies allow for real-time monitoring and control of energy usage, enabling adjustments to optimize performance and minimize waste.

Employee Training and Awareness Programs

Employee training and awareness programs play a vital role in fostering a culture of energy conservation within the organization. Engaging employees in energy-saving initiatives encourages their active participation and fosters a sense of shared responsibility. This collaborative approach can lead to significant reductions in energy consumption across the organization.

By educating employees about energy-efficient practices, the company can motivate them to adopt sustainable behaviors in their daily work routines. This includes promoting the use of energy-efficient appliances and equipment, and encouraging the adoption of better work practices that minimize energy consumption.

Process Optimization Strategies

Process optimization strategies are essential for identifying and eliminating energy-consuming inefficiencies within the operational workflow. This involves streamlining processes to reduce energy waste and enhance productivity. A thorough analysis of existing procedures and workflows is critical for identifying potential improvements.

Implementing innovative approaches and technologies can significantly reduce energy consumption in various processes. For example, introducing lean manufacturing principles can streamline production lines, minimize waste, and ultimately reduce energy consumption.

Maintenance and Repair Programs

Regular maintenance and repair programs are crucial for ensuring the efficient operation of energy-consuming equipment. Addressing potential issues promptly prevents further energy waste and extends the lifespan of equipment. A well-defined maintenance schedule ensures that equipment operates at peak efficiency, minimizing energy losses and maximizing performance.

Proactive maintenance also helps in preventing costly breakdowns and repairs, further contributing to the long-term cost-effectiveness of the operation.

Data Analysis and Reporting

Comprehensive data analysis and reporting are essential for tracking energy usage trends and identifying areas for improvement. Analyzing energy consumption patterns and comparing them with historical data provides valuable insights into operational efficiency. Using this data, the organization can pinpoint energy-intensive processes and implement targeted solutions.

Regular reporting on energy consumption helps to monitor progress towards energy-saving goals and identify any emerging issues. This data-driven approach empowers organizations to make informed decisions and optimize energy usage strategies.