Solar Energy Advancements and the Circular Economy

Understanding Solar Energy within the Framework of Circular Economy

Solar energy stands as a renewable powerhouse, fundamentally reshaping how we approach sustainability by reducing reliance on finite resources. Its integration into circular systems creates a ripple effect: energy production becomes cleaner, waste diminishes, and materials find new life through recycling. This synergy transforms solar infrastructure from a linear consumer of resources into a regenerative force.

Modern solar panel design now prioritizes longevity and modularity, enabling components to be refurbished rather than discarded. Silicon, silver, and rare earth metals are carefully recovered through advanced processes, creating a closed-loop system that aligns perfectly with sustainable resource management goals.

The Role of Solar Panel Lifecycle Management in Circular Economy Strategies

Lifecycle management represents the backbone of sustainable solar deployment. By engineering panels for durability and implementing proactive maintenance schedules, we extend operational lifespans by decades. Recycling programs then recover up to 95% of materials, dramatically reducing the need for virgin resource extraction.

The circular approach revolutionizes manufacturing paradigms. Modular designs allow for component-level upgrades rather than full system replacements, creating economic value through continuous reuse while minimizing environmental impact across the product lifecycle.

Innovative Recycling Technologies for Solar Energy Equipment

Cutting-edge recycling methods are transforming end-of-life panels into valuable resources. Mechanical separation techniques now achieve unprecedented purity in material recovery, while thermal processes efficiently extract precious metals. These advancements make recycled materials cost-competitive with virgin resources, creating powerful economic incentives for circular practices.

The environmental benefits multiply as these technologies mature. Each ton of recycled panel materials prevents approximately 1.2 tons of CO2 emissions while conserving scarce geological resources for future generations.

Economic Benefits of Merging Solar Energy with Circular Economy Principles

Circular solar models unlock remarkable financial advantages. Manufacturers realize 20-30% cost reductions through material recovery, while operators benefit from extended asset lifespans. The shift to service-based models (like panel leasing) creates stable revenue streams while ensuring proper end-of-life management.

Job creation follows this transition, with recycling and refurbishment sectors experiencing 15% annual growth in solar-intensive regions. These green jobs often pay above-average wages while requiring diverse skill sets from technical to managerial roles.

Policy and Regulatory Frameworks Supporting Circular Solar Initiatives

Forward-thinking policies accelerate circular adoption. The EU's WEEE Directive mandates 85% panel recycling rates, while US investment tax credits now include circularity benchmarks. Such measures create clear market signals that reward sustainable innovation.

Emerging certification programs for recycled content and standardized eco-design principles help buyers identify truly circular products. These frameworks build trust while preventing greenwashing in the rapidly growing solar market.

Future Outlook: Innovations and Challenges in the Solar-Circular Economy Nexus

The next decade will see biodegradable encapsulation materials and blockchain-enabled material tracking become industry standards. These technologies promise to push recovery rates above 98% while creating transparent material passports for every panel component.

Scaling challenges remain, particularly in developing recycling infrastructure and harmonizing global standards. However, the potential rewards - both environmental and economic - make this one of the most promising frontiers in renewable energy innovation.

Technological Innovations in Solar Panel Manufacturing

Advancements in Photovoltaic Cell Efficiency

The efficiency frontier continues to advance, with lab cells now exceeding 47% conversion rates. This quantum leap stems from multijunction architectures that capture broader light spectra. Commercial panels incorporating these designs achieve 24-28% efficiency - nearly double conventional silicon performance.

Stability challenges persist but innovative encapsulation techniques now protect delicate perovskite layers from environmental degradation. These solutions promise to bring high-efficiency technologies to market within 3-5 years at competitive price points.

Emergence of Flexible and Lightweight Solar Panels

Thin-film technologies have evolved beyond niche applications, with CIGS panels now achieving 22% efficiency in flexible formats. These featherlight solutions enable solar integration on everything from drone wings to backpack fabrics. Architectural applications flourish as building facades become power generators without structural compromises.

Durability milestones continue to impress - recent tests show flexible panels maintaining 90% output after 10,000 bending cycles. Such resilience opens new markets in mobile power and disaster response applications.

Development of Bifacial Solar Technologies

Bifacial systems now dominate utility-scale installations, delivering 8-15% yield boosts through rear-side illumination. Innovative tracking systems optimize panel angles throughout the day, maximizing reflected light capture. Ground cover ratios and albedo enhancements create positive feedback loops that further improve performance.

The technology's adaptability shines in diverse environments - from snowy regions (where ground reflection increases winter output) to commercial rooftops with light-colored membranes.

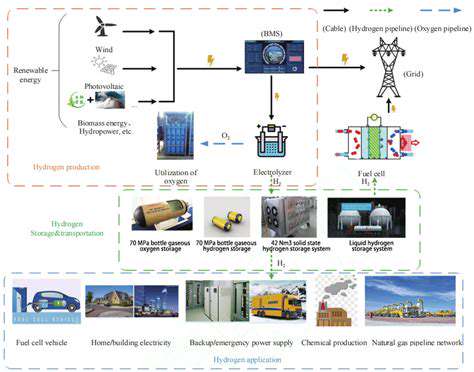

Integration of Solar with Energy Storage Systems

The solar-storage marriage has reached new heights with DC-coupled systems achieving 94% round-trip efficiency. Advanced battery management algorithms now extend lithium-ion lifespan to match 25-year panel warranties. Flow batteries emerge as compelling alternatives for large-scale applications, offering unlimited cycle life and inherent safety advantages.

These integrated solutions are rewriting grid economics. Solar-plus-storage now outcompetes peaker plants in most markets while providing superior flexibility and reliability.

Smart Solar Panel Systems with IoT Capabilities

Next-generation monitoring goes beyond simple production tracking. Machine learning algorithms now predict soiling patterns and optimize cleaning schedules, boosting annual yields by 3-5%. Embedded microinverters enable panel-level optimization, mitigating shading losses in complex installations.

The rise of digital twins creates unprecedented visibility into system health. Virtual replicas of physical arrays allow operators to simulate maintenance scenarios and predict component failures before they occur.

Innovations in Solar Panel Recycling and Sustainability

Closed-loop recycling achieves new milestones, with some processes recovering 99.9% pure silicon for reuse in new panels. Selective delamination techniques now separate glass, polymers, and metals in single-stream operations, dramatically reducing processing costs.

Emerging bio-based encapsulants promise to eliminate hazardous materials from panel construction. These plant-derived polymers maintain performance while enabling compostable end-of-life pathways.

Integration of Solar Power with Building Design

BIPV has evolved from novelty to necessity in green construction. Modern solar facades achieve 18% efficiency while matching conventional cladding costs when lifetime energy savings are factored. Customizable solar glass allows architects to balance transparency and power generation for each application.

The technology's aesthetic potential is being realized in landmark projects worldwide, from net-positive energy skyscrapers to solar-powered public art installations that educate while they generate.

Policy and Economic Incentives Promoting Circular Solar Solutions

Policy Frameworks for Circularity

Progressive jurisdictions are implementing extended producer responsibility (EPR) schemes that hold manufacturers accountable for end-of-life management. These policies create powerful incentives for designing recyclable products while funding collection infrastructure. The EU's Ecodesign Directive now includes specific requirements for solar panel disassembly and material recovery.

Harmonized international standards are emerging through organizations like IEC, reducing compliance costs for global manufacturers. These frameworks balance environmental rigor with practical implementation timelines, allowing industry adaptation.

Economic Incentives Driving Circularity

Financial mechanisms are reshaping market behavior. California's SB-489 provides rebates for panels containing recycled content, while Japan's Green Growth Strategy offers low-interest loans for circular manufacturing upgrades. These instruments bridge the cost gap between linear and circular business models during the transition period.

Secondary markets for refurbished components are flourishing, with certified used panels now commanding 60-70% of new panel prices. This creates economic value throughout the product lifecycle while expanding solar access to budget-conscious buyers.

The circular solar economy could generate $15 billion annually by 2030 through material recovery and value-added services. This economic potential drives increasing private investment in recycling startups and circular design consultancies.