The Future of Wind Energy Advancements Materials

The Role of Nanotechnology in the Future of Wind Energy

Enhancing Turbine Efficiency

Nanotechnology offers exciting possibilities for improving the efficiency of wind turbines. By incorporating nanomaterials into turbine blades, researchers aim to reduce friction and drag, leading to a significant increase in energy capture. This enhanced efficiency translates directly to a higher yield of electricity from the same wind resource, making wind energy a more competitive and sustainable energy source. This could potentially revolutionize the economics of wind energy production, making it more attractive to investors and governments.

Nanomaterials like carbon nanotubes and graphene, known for their exceptional strength and lightweight properties, could be used to reinforce blade structures, allowing for the creation of larger and more powerful turbines. This advancement could significantly increase the amount of energy generated, contributing to a more sustainable energy future.

Improving Durability and Longevity

One of the significant challenges facing wind turbines is their susceptibility to corrosion, wear, and fatigue, especially in harsh and demanding environments. Nanotechnology provides a solution by creating protective coatings and reinforcements that can extend the lifespan of turbine components. These advanced coatings, incorporating nanoparticles, can create a barrier against environmental degradation, ensuring that wind turbines operate reliably and efficiently for decades to come.

By enhancing the durability of turbine components, nanotechnology contributes to reduced maintenance costs and minimized downtime. This translates into a more economical and sustainable energy production process, ultimately benefiting both the environment and the economy.

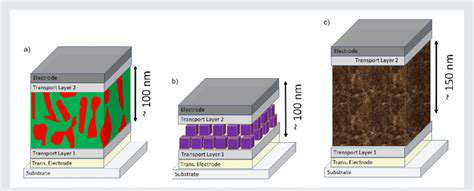

Optimizing Materials for Manufacturing

Nanotechnology's influence extends beyond the turbine itself to the manufacturing processes involved. Nanomaterials can be incorporated into the production of composites, resins, and other materials used in the construction of wind turbines. This can result in lighter, stronger, and more cost-effective components, streamlining the manufacturing process and potentially reducing the overall cost of wind energy.

These advancements in materials science could lead to significant reductions in the manufacturing costs associated with wind turbines, making them more accessible and affordable for both large-scale installations and smaller-scale projects, thereby increasing the global adoption of wind energy.

Advanced Sensor Integration

Nanotechnology's ability to miniaturize and integrate sensors provides valuable insights into the performance and health of wind turbines. By incorporating nanoscale sensors into turbine blades, researchers can monitor stress levels, detect early signs of wear and tear, and predict potential failures. This real-time data analysis allows for proactive maintenance, reducing downtime and maximizing energy generation.

This real-time monitoring capability, powered by nanotechnology, enables predictive maintenance strategies, significantly reducing operational costs and optimizing the overall efficiency of wind energy systems. It also facilitates the development of more robust and reliable wind turbine designs.

Creating Self-Cleaning Surfaces

Wind turbine blades are constantly exposed to harsh environmental conditions, including dust, dirt, and pollutants. Nanotechnology can be used to create self-cleaning surfaces on turbine components. These surfaces, engineered with special nanostructures, can repel dirt and debris, ensuring optimal airflow and minimizing performance degradation. This translates to increased energy production and reduced maintenance requirements.

Enhancing Energy Storage Capabilities

Integrating nanomaterials into energy storage systems, such as batteries, is another area where nanotechnology can significantly impact the future of wind energy. Nanostructured materials can enhance battery performance, increasing their capacity and lifespan, which is crucial for storing the intermittent energy generated by wind turbines. These advancements in energy storage are essential for bridging the gap between the intermittent nature of wind power and the continuous demands of the grid.

Addressing Environmental Concerns

The environmental impact of wind energy production is a critical consideration. Nanotechnology can play a role in minimizing the environmental footprint of wind turbines, from the manufacturing process to the disposal of components. The development of sustainable and biodegradable nanomaterials in turbine construction and maintenance could create a more environmentally friendly energy sector. This approach is crucial for ensuring that wind energy remains a truly sustainable and responsible energy source.