Cryogenic Energy Storage: Liquid Air for Grid Scale Storage

The process of creating liquid air involves the meticulous compression and subsequent cooling of ambient air. This intricate process, while seemingly straightforward, requires sophisticated equipment and precise control. High-pressure compressors are crucial for raising the air's density, setting the stage for the subsequent cooling steps. This initial compression significantly increases the air's temperature, necessitating a series of heat exchangers and refrigeration cycles. Subsequently, the compressed air is cooled to extremely low temperatures, typically below -190°C, enabling its transition into a liquid state. This entire process demands a high degree of precision and control, ensuring the efficient and reliable production of liquid air for energy storage.

Various methods are employed to achieve this cryogenic cooling, ranging from multi-stage compression to advanced refrigeration techniques. Each method has its own set of advantages and disadvantages, influencing the overall efficiency and cost-effectiveness of the liquid air production process. Understanding these nuances is critical for optimizing the entire energy storage cycle and maximizing the benefits of cryogenic energy storage.

Storage Tanks and Containment: Crucial Components

The storage tanks, designed to house the liquid air, are paramount to the successful implementation of liquid air energy storage. These specialized tanks, often constructed from high-strength, cryogenic-resistant materials, are engineered to withstand the extreme pressures and temperatures inherent in liquid air storage. The insulation systems used within these tanks play a vital role in minimizing heat transfer from the surroundings, preventing the liquid air from vaporizing prematurely and thus ensuring the long-term viability of the storage process. Proper tank design and maintenance are essential to prevent leaks and maintain the integrity of the storage system.

Furthermore, the containment systems must be rigorously tested and inspected to guarantee their ability to withstand the substantial pressures and temperatures involved in storing liquid air. This rigorous testing process is critical in preventing any potential safety hazards associated with the storage of such a cryogenic substance. The integrity of these containment systems is paramount to the safe and effective operation of liquid air energy storage systems.

Regenerative Conversion: Recovering Stored Energy

Recovering the stored energy in liquid air involves a process of controlled vaporization, converting the liquid back into gaseous air. This process is carefully managed to extract the maximum amount of energy and to minimize energy losses during the transition. The energy released during the vaporization process can then be used to drive turbines, generators, or other energy conversion devices. The efficiency of this conversion process is a key factor in determining the overall performance of the liquid air energy storage system.

Careful consideration of the vaporization process is crucial. The rate of vaporization, the pressure conditions, and the heat exchange mechanisms all contribute to the overall efficiency of the energy recovery process. Optimizing these parameters is essential for maximizing the usable energy extracted from the stored liquid air and minimizing the energy losses inherent in the conversion process.

Economic and Environmental Considerations

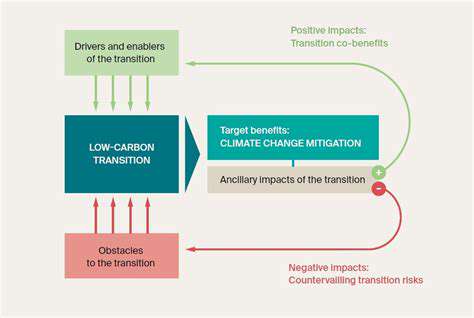

The economic viability of liquid air energy storage depends heavily on factors such as the cost of equipment, the efficiency of the conversion processes, and the availability of suitable sites for the storage facilities. The overall cost-benefit analysis needs to be carefully evaluated to ensure the long-term profitability of the system. Furthermore, the environmental impact of the production and use of liquid air energy storage systems should be considered, including the energy consumption associated with the production of liquid air and the potential for greenhouse gas emissions.

The environmental footprint of liquid air energy storage needs careful analysis to assess its sustainability. The energy consumption during the air compression and cooling phases, as well as the potential for emissions during the manufacturing of components, need to be evaluated and mitigated. Ultimately, the economic and environmental factors must align to ensure the long-term viability and sustainability of this promising energy storage solution.

Dyeing fabrics and textiles has captivated humans for millennia, transforming raw materials into vibrant expressions of creativity and artistry. From the ancient Egyptians' use of natural pigments to the modern synthesis of chemical dyes, the pursuit of color has been a driving force in fashion, art, and industry. The journey of color has been intertwined with human civilization, and the evolution of dyeing techniques reflects our cultural and technological advancements.

Economic Viability and Potential Applications

Economic Viability of Liquid Air Energy Storage

Assessing the economic viability of liquid air energy storage (LAES) is crucial for its widespread adoption. While the upfront capital costs for building and maintaining the cryogenic infrastructure can be significant, the potential for cost savings in the long run through reduced reliance on fossil fuels and potentially lower electricity prices during peak demand periods makes it an attractive proposition. Detailed cost-benefit analyses are needed to account for factors like the cost of electricity, the cost of compressed air, the efficiency of the liquefaction process, and the lifespan of the system. Furthermore, government incentives and subsidies could significantly influence the economic feasibility of LAES projects.

The economics of LAES hinges on a number of key factors, including the cost of electricity and the cost of the cryogenic equipment involved. If electricity prices are high and volatile, and the cost of cryogenic equipment decreases, LAES has the potential to become a competitive energy storage solution. Government policies can play a significant role by providing incentives for the development and deployment of LAES technology, encouraging investment and technological advancements.

Potential Applications in Power Generation

Liquid air energy storage (LAES) has the potential to revolutionize power generation by providing a solution for storing energy generated during periods of high renewable energy production. This stored energy can then be released during periods of low renewable energy generation or high electricity demand, effectively smoothing out the intermittent nature of solar and wind power. The ability of LAES to provide dispatchable power makes it a valuable asset in the grid infrastructure.

Integrating LAES into power grids is a significant step towards achieving a more sustainable and reliable energy future. This technology can help to balance the grid, reducing the need for fossil fuel plants during periods of low renewable energy availability. Furthermore, it can provide grid stability by providing a quick response to fluctuations in demand.

Applications in Transportation Sector

The transportation sector presents another promising application for cryogenic energy storage in the form of liquid air. While not as immediately apparent as in the power sector, the concept of using LAES for fuel cells or other forms of transportation power could offer a significant leap forward in sustainable transportation. This approach could provide a clean, efficient, and potentially more cost-effective alternative to traditional fuels, paving the way for environmentally friendly vehicles.

Environmental Impact Considerations

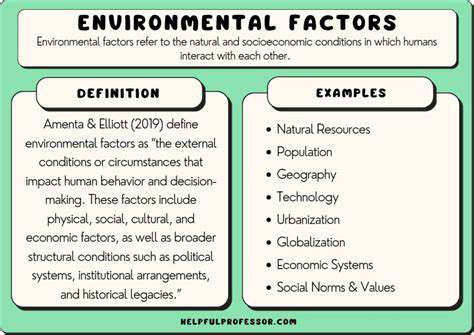

The environmental impact of LAES is a crucial aspect to consider, as it involves cryogenic processes and potentially large-scale infrastructure. Careful evaluation of the environmental footprint, including the energy consumption for liquefaction, the greenhouse gas emissions associated with the production of electricity for the process, and the potential environmental impacts of the storage facility, is necessary. Minimizing the environmental impact of LAES is crucial for its long-term acceptance and sustainability.

Technological Advancements and Research

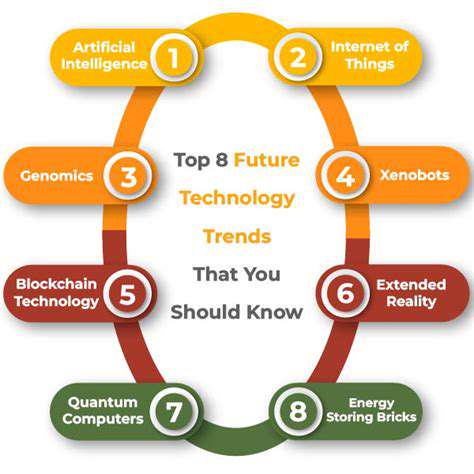

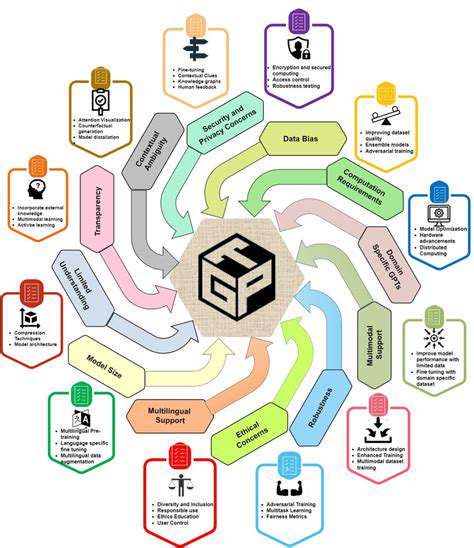

Significant technological advancements are needed to improve the efficiency and reduce the cost of LAES. Research focused on optimizing the liquefaction process, improving the insulation of the storage tanks, and developing more robust and durable cryogenic components is essential to unlock the full potential of this technology. Further research into the integration of LAES with other renewable energy sources and smart grid technologies will be critical for its successful deployment.

Comparison with Other Energy Storage Technologies

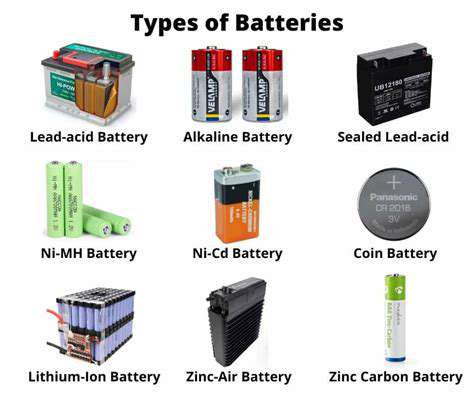

LAES needs to be compared with other energy storage technologies like batteries, pumped hydro, and compressed air energy storage (CAES). Understanding the strengths and weaknesses of each technology in terms of cost, efficiency, scalability, and environmental impact is vital for determining the optimal solution for various applications. A comprehensive comparison helps identify the specific situations where LAES offers the most compelling advantages.