The Impact of IoT on Solar Energy Performance

Automated System Control and Optimization

Automated System Control: A Foundation for Efficiency

Automated system control plays a crucial role in modern industries, streamlining operations and optimizing resource utilization. By automating tasks that were previously performed manually, businesses can significantly reduce operational costs and improve overall efficiency. This automation allows for consistent, predictable results, eliminating human error and ensuring higher quality output.

The implementation of automated control systems often leads to reduced labor costs and increased productivity. This is particularly true in manufacturing and logistics, where repetitive tasks can be handled by machines, freeing up human workers for more complex and strategic roles.

Optimizing System Performance Through Data Analysis

A key component of automated system control is the integration of data analysis. By collecting and analyzing data from various sources within the system, we can gain valuable insights into its performance and identify areas for improvement. This data-driven approach allows for proactive adjustments, preventing potential issues and maintaining optimal system performance.

Data analysis provides a clear picture of system bottlenecks and inefficiencies. This allows for targeted interventions, leading to a more streamlined and productive system. Moreover, historical data can be used to predict future trends and adapt the system accordingly.

Real-Time Adjustments and Dynamic Control

Advanced automated control systems are capable of making real-time adjustments to maintain optimal performance. This dynamic control capability allows for immediate responses to changing conditions, ensuring the system always operates at peak efficiency. The ability to react quickly to fluctuations in demand or unexpected events is crucial in maintaining stability and minimizing downtime.

Real-time adjustments are vital in industries where quick responses are paramount. This is especially true in sectors like energy management and financial markets, where constant monitoring and adjustments are necessary to maintain equilibrium and profitability.

Integration with External Systems and Data Sources

Modern automated systems are increasingly designed to seamlessly integrate with other systems and external data sources. This interconnectivity allows for a holistic view of the entire operation, enabling comprehensive control and optimization. Integration with supply chain management systems, customer relationship management systems, and other relevant platforms provides a more complete picture of the business environment.

Integration with external systems provides a more unified and comprehensive view of the entire operation. This allows for better decision-making and more effective resource allocation, leading to improved overall business performance.

Enhanced Security and Compliance Measures

Automated systems often require robust security measures to protect sensitive data and ensure compliance with relevant regulations. Implementing secure protocols and access controls is critical to safeguarding the integrity of the system and the data it processes. This is particularly important in industries with strict regulatory requirements, such as healthcare and finance.

Security is paramount in automated systems, especially those handling sensitive information. Robust security measures are essential to protect against unauthorized access and cyber threats, ensuring the confidentiality and integrity of data.

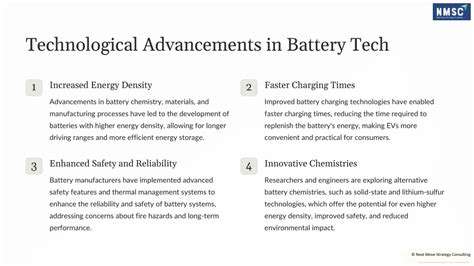

Future Trends and Innovations in Automation

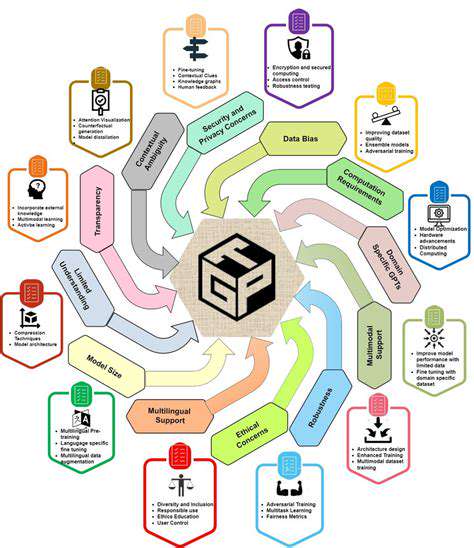

The field of automated system control is constantly evolving, with new technologies and innovations emerging regularly. Artificial intelligence (AI) and machine learning (ML) are playing increasingly important roles in optimizing systems. These technologies are capable of learning from historical data and making predictions to further enhance control and efficiency. This trend is expected to continue, leading to even more sophisticated and adaptable automated systems in the future.

AI and ML are revolutionizing the way automated systems are designed and operated. These technologies are capable of analyzing complex data patterns and making intelligent decisions, leading to significant improvements in system performance and adaptability. The future of automated control systems is bright.