Next Generation Wind Turbine Blade Aerodynamics and Control Systems: Enhanced Energy Capture

Advanced Blade Aerodynamics: Shaping the Flow for Maximum Efficiency

Understanding the Fundamentals of Airfoil Design

Airfoil design is paramount to blade aerodynamics. A well-designed airfoil, the cross-sectional shape of the blade, dictates how air flows over and around it. Understanding the principles of lift and drag, generated by the interaction of air with the airfoil's shape, is crucial. The camber, the curvature of the airfoil, plays a significant role in generating lift, while the thickness and leading/trailing edge shapes influence drag and overall efficiency. Different airfoil shapes are optimized for various flight conditions and blade applications, highlighting the importance of careful selection.

Analyzing the impact of Reynolds number, a dimensionless quantity representing the ratio of inertial forces to viscous forces, is also vital. Different Reynolds numbers lead to different flow regimes, impacting the aerodynamic performance of the blade. Consequently, an airfoil designed for high Reynolds number conditions might not perform as efficiently at low Reynolds numbers, underscoring the need for tailored designs across diverse operating scenarios.

Optimizing Blade Profiles for Reduced Drag

Minimizing drag is a key aspect of maximizing blade efficiency. Drag forces, which oppose the motion of the blade, result from various factors such as friction along the surface and pressure differences across the airfoil. Careful contouring of the blade's leading and trailing edges, as well as the overall shape, can significantly reduce these drag forces.

Implementing techniques like laminar flow control, which aims to maintain smooth airflow across the blade surface, can further reduce drag. This can involve the use of specialized surface textures or coatings to encourage the formation of a laminar boundary layer, thereby minimizing frictional drag and enhancing overall efficiency. These strategies are particularly important in high-speed applications where drag reduction translates directly to improved performance.

Exploring Advanced Computational Fluid Dynamics (CFD) Techniques

Computational fluid dynamics (CFD) has become an indispensable tool in blade design optimization. CFD simulations allow engineers to virtually test different blade configurations and airfoil designs, analyzing the airflow patterns and identifying potential areas for improvement.

These simulations provide detailed insights into the flow characteristics, including velocity, pressure, and turbulence, allowing for a comprehensive understanding of the aerodynamic behavior of the blade.

The Role of Blade Geometry in Vortex Management

Understanding and managing the formation and shedding of vortices is crucial for optimal blade performance. Vortices, swirling masses of air, can significantly impact blade efficiency by generating additional drag and potentially leading to instability. Careful consideration of the blade's geometry, including the leading edge shape and trailing edge design, can influence the formation and dissipation of these vortices.

Analyzing vortex shedding patterns and their impact on blade performance is vital. By optimizing the blade geometry, engineers can aim to reduce vortex formation, minimize associated drag, and ensure stable operation across a range of flight conditions. This is a key element in the advancement of blade aerodynamics and its application in next-generation energy and transportation systems.

Integrating Materials Science for Enhanced Performance

The selection of appropriate materials is crucial for the design of high-performance blades. Materials with specific properties, such as high strength-to-weight ratios and resistance to fatigue, are essential for ensuring the longevity and reliability of the blades. Advanced composite materials, for example, are often explored for their potential to enhance strength and reduce weight, ultimately improving blade efficiency.

The interplay between material properties and aerodynamic design must be carefully considered. The ability of a material to withstand the stresses and strains imposed by airflow and structural loads is a key factor in determining the overall performance and durability of the blade. The integration of advanced materials science with cutting-edge aerodynamic principles will pave the way for even more efficient and durable blade designs in the future.

The Future of Wind Power: Integration and Optimization

Harnessing the Power of the Wind: A Sustainable Future

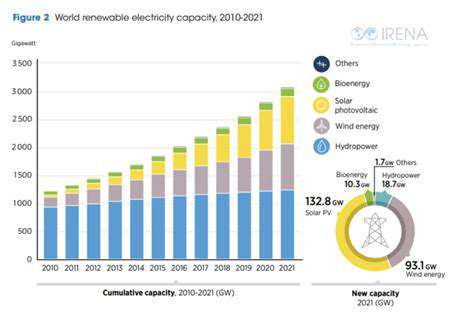

Wind power is rapidly emerging as a crucial component of a sustainable energy future. Its potential to generate clean, renewable energy is undeniable, offering a significant alternative to fossil fuels. The technology is constantly evolving, leading to increased efficiency and lower costs, making it an increasingly attractive option for countries and communities seeking to reduce their carbon footprint and embrace cleaner energy solutions.

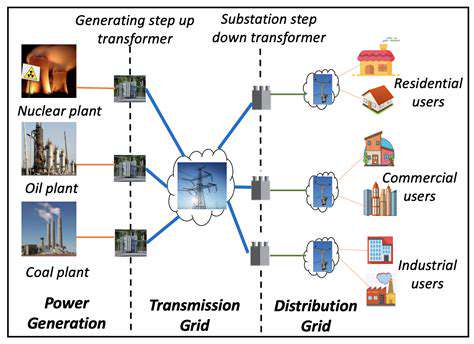

The integration of wind power into existing energy grids is a complex but achievable goal. Advancements in energy storage technologies are paving the way for more reliable and consistent power generation, overcoming the intermittent nature of wind. This advancement is crucial for widespread adoption and further development of this renewable energy source.

Technological Advancements Driving Innovation

Significant advancements in turbine design are resulting in larger, more powerful wind turbines that can capture greater amounts of wind energy. This increased efficiency translates directly into more energy generated per turbine, bolstering the overall capacity of wind farms.

The development of sophisticated wind forecasting models plays a critical role in optimizing wind farm operations. These models allow for better predictions of wind patterns, enabling operators to schedule turbine output to match energy demand more accurately. This results in enhanced grid stability and reduced energy waste.

Grid Integration Challenges and Solutions

One of the key challenges in integrating wind power is the intermittency of wind. This means that wind speeds fluctuate, sometimes resulting in periods of low or no wind. This inconsistency can put a strain on the electricity grid, requiring sophisticated grid management strategies.

Innovative solutions, such as smart grids and energy storage technologies, are being developed to address this challenge. These technologies allow the grid to manage fluctuations in wind power output effectively, ensuring a steady and reliable supply of electricity. This is a crucial component for a successful transition to a renewable energy future.

Economic Impacts and Job Creation

The expansion of wind power projects creates significant economic opportunities. New manufacturing jobs are created in the production of turbines, components, and associated equipment. Furthermore, the deployment of wind farms stimulates investment and economic growth in local communities.

The reduced reliance on fossil fuels also translates into significant cost savings for consumers and governments, particularly in the long term. These savings come from reduced emissions and the avoidance of costly subsidies for fossil fuel production. This economic advantage further solidifies the appeal of wind power.

Environmental Benefits and Sustainability

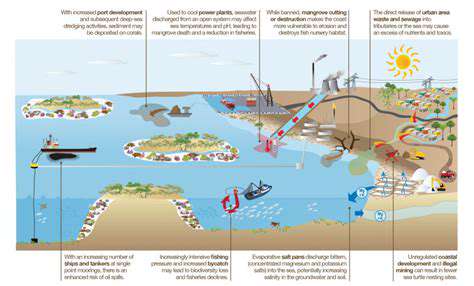

Wind power has a remarkably low environmental impact compared to fossil fuel power plants. It produces no greenhouse gas emissions during operation, contributing to a cleaner and healthier environment. This is a significant benefit, especially in light of the urgent need to address climate change and its consequences.

The use of wind energy minimizes the release of harmful pollutants into the atmosphere, improving air quality and mitigating health risks associated with air pollution. This positive environmental impact is a compelling reason to embrace wind energy as a primary source of power.

Public Perception and Policy Support

Public perception of wind power is evolving, with growing support for renewable energy sources. Education and outreach initiatives are crucial in addressing concerns and promoting understanding of the benefits of wind energy.

Government policies play a crucial role in fostering the growth of wind power. Incentives, regulations, and supportive policies can encourage investment, accelerate deployment, and create a more favorable environment for the development of wind energy projects.