Corporate Renewable Procurement Specific Industries & Applications

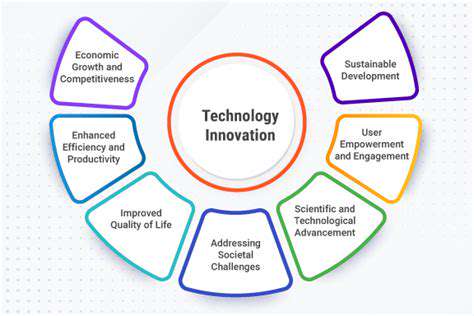

The Digital Revolution's Impact

The digital revolution has fundamentally altered how we live, work, and interact with the world around us. This transformation has been driven by advancements in computing power, data storage, and communication technologies. The sheer volume of data generated daily, coupled with the ability to process it at lightning speed, has unlocked unprecedented opportunities for innovation across various industries.

From personalized medicine to sophisticated financial models, the digital age has enabled breakthroughs that were once unimaginable. The interconnected nature of digital systems has fostered collaboration and knowledge sharing on a global scale, accelerating progress in scientific discovery and technological advancement.

Data-Driven Decision Making

A crucial aspect of modern technology is its ability to collect, analyze, and interpret vast amounts of data. This capability allows businesses and organizations to make informed decisions based on evidence rather than intuition. By leveraging data analytics, companies can identify trends, optimize processes, and personalize customer experiences, ultimately leading to improved efficiency and profitability.

This data-driven approach is especially valuable in fields like healthcare, where it can be used to identify patterns in patient data and predict potential health risks. Predictive modeling using data analytics is crucial to preventative medicine.

Artificial Intelligence's Growing Role

Artificial intelligence (AI) is rapidly transforming industries, automating tasks, and enabling new levels of efficiency. From self-driving cars to personalized recommendations on streaming services, AI is becoming increasingly integrated into our daily lives. AI algorithms are capable of learning from data, identifying patterns, and making decisions with minimal human intervention.

The Internet of Things (IoT): Connecting the Physical World

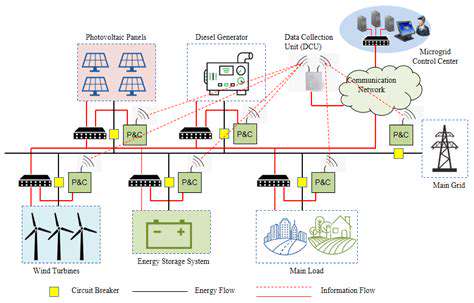

The Internet of Things (IoT) is revolutionizing how we interact with the physical world. By connecting everyday objects to the internet, IoT allows for greater automation, remote monitoring, and data collection. Imagine smart homes that adjust lighting and temperature based on your preferences, or industrial sensors that monitor equipment performance in real-time. These applications are just a glimpse into the vast potential of IoT.

This interconnected network of devices creates a wealth of data that can be analyzed to improve efficiency and optimize processes across a broad range of industries. This data collection plays an important role in the development of intelligent systems.

Cybersecurity: Protecting the Digital Landscape

As technology advances, so does the need for robust cybersecurity measures. Protecting sensitive data and systems from malicious actors is paramount in today's interconnected world. Cybersecurity threats are constantly evolving, demanding continuous vigilance and innovation in defense strategies. This includes developing advanced encryption techniques, implementing intrusion detection systems, and educating users on safe online practices.

Robust cybersecurity measures are critical for maintaining the integrity and confidentiality of sensitive information, and mitigating the risks associated with data breaches. It is essential for the continued growth and development of technology.

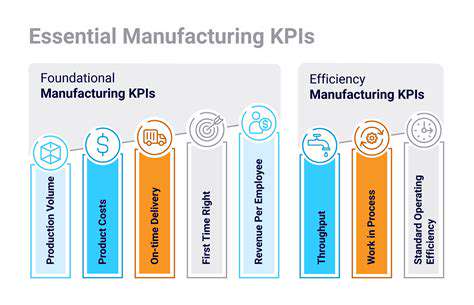

Manufacturing: Optimizing Processes for Sustainability

Material Selection and Procurement

A crucial aspect of optimizing manufacturing processes is the careful selection of materials. Choosing the right material directly impacts the efficiency and cost-effectiveness of the entire production line. This involves considering factors like strength, durability, cost, availability, and environmental impact. Proper material selection can significantly reduce waste and improve product quality, leading to overall cost savings.

Robust procurement strategies are equally important. This includes establishing reliable supplier relationships, ensuring timely delivery, and managing inventory effectively. Efficient procurement practices minimize disruptions and maintain a consistent flow of materials throughout the production process. This streamlines operations and reduces the risk of delays and bottlenecks.

Process Design and Engineering

Optimizing manufacturing processes necessitates a thorough understanding of the entire production flow. This includes identifying bottlenecks, inefficiencies, and areas for improvement. Detailed process design and engineering are essential to achieve maximum output with minimal waste and human error.

Careful consideration should be given to the sequence of operations. A well-designed workflow minimizes material handling, reduces production time, and improves overall productivity. This can lead to significant reductions in production costs and improved product quality.

Quality Control and Assurance

Implementing robust quality control measures is essential for ensuring product consistency and meeting customer expectations. Quality control ensures that products meet the predefined standards and specifications. This process not only enhances customer satisfaction but also reduces defects and rework, minimizing costs associated with failures.

Implementing rigorous testing procedures at various stages of the production process is critical. This ensures that products meet the required standards and reduces the likelihood of defects reaching the customer. Effective quality assurance strategies minimize costly recalls and maintain a positive brand image.

Lean Manufacturing Principles

Integrating lean manufacturing principles into the production process can dramatically improve efficiency and reduce waste. Lean principles focus on eliminating non-value-added activities, improving workflow, and optimizing resource utilization. This results in a more streamlined and efficient production process, leading to significant cost savings.

Implementing 5S methodology, for example, helps maintain a clean and organized workspace. This leads to increased productivity, reduced errors, and improved safety conditions within the manufacturing environment. The overall effect is a more efficient use of resources and time.

Automation and Technology Integration

Utilizing automation technologies and advanced machinery can significantly enhance production efficiency. Automation can handle repetitive tasks, leading to increased speed and accuracy. This reduces labor costs and improves output per unit of time.

Integrating advanced technologies like robotics, AI, and data analytics helps to optimize decision-making and improve predictive capabilities. This allows for proactive problem-solving and minimizes downtime, ultimately increasing overall productivity.

Supply Chain Management

A well-managed supply chain is essential for maintaining a consistent flow of materials and components throughout the production process. This includes optimizing supplier relationships, establishing clear communication channels, and ensuring timely delivery. Strong supply chain management reduces lead times and minimizes disruptions, ensuring smooth production operations.

Efficient inventory management is crucial to maintain optimal stock levels and reduce storage costs. Effective inventory control helps prevent stockouts and excess inventory, ensuring that materials are available when needed. This reduces waste and maximizes the efficiency of the entire manufacturing process.

Employee Training and Skill Development

Investing in employee training and skill development is vital for a successful manufacturing operation. Providing employees with the necessary skills and knowledge enables them to perform their tasks efficiently and effectively. This leads to improved productivity, reduced errors, and a more engaged workforce.

Continuous training and development programs can enhance the skills of the workforce and keep them updated with the latest industry best practices. This is crucial to maintain a competitive advantage in the rapidly evolving manufacturing landscape.

3D printing technologies are fundamentally reshaping production paradigms across industries. These methods enable fabrication of geometrically complex parts that would be prohibitively expensive or technically impossible to create using conventional manufacturing approaches. The unparalleled design freedom and rapid prototyping capabilities represent transformative advantages of additive techniques.

Transportation: Electrifying the Future with Sustainable Fuels

Electric Vehicle Adoption: A Growing Trend

The global adoption of electric vehicles (EVs) is rapidly accelerating, driven by a confluence of factors, including government incentives, decreasing battery costs, and increasing range anxiety reduction. This shift towards EVs is a crucial step in transitioning to a more sustainable transportation future, offering significant environmental benefits by reducing greenhouse gas emissions compared to traditional gasoline-powered vehicles. This transition is also creating new opportunities for innovation and economic growth in the renewable energy sector, which is central to powering these vehicles.

Sustainable Fuels: Beyond Batteries

While electric vehicles are gaining popularity, the development and widespread adoption of sustainable fuels, such as biofuels and hydrogen, represent another crucial avenue for electrifying transportation. These alternative fuels can power existing internal combustion engine vehicles, potentially reducing the need for complete vehicle replacement and facilitating a smoother transition. This approach also presents unique opportunities for companies to invest in renewable energy sources and develop infrastructure to support the production and distribution of these fuels.

Infrastructure Development: Charging and Refueling Networks

A critical component of successful EV adoption is the development of robust charging and refueling infrastructure. This includes building extensive networks of charging stations across different locations, from residential areas to major highways, ensuring convenient access for drivers. Furthermore, the infrastructure needs to incorporate smart grid technologies to manage energy flow efficiently and maximize renewable energy integration into the system. This investment in infrastructure is essential for establishing the necessary support systems for sustainable transportation.

Corporate Responsibility in Sustainable Transportation

Corporations play a pivotal role in driving the transition to sustainable transportation. By investing in research and development of sustainable fuels, supporting EV adoption through incentives or partnerships, and investing in charging infrastructure, companies can demonstrate their commitment to environmental responsibility. This commitment extends beyond immediate profit and encompasses long-term sustainability goals, recognizing the importance of mitigating climate change and creating a more environmentally friendly future for all.

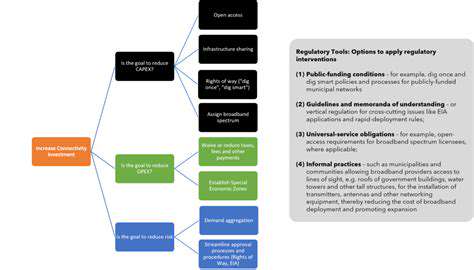

Policy and Regulatory Frameworks: Fostering Innovation

Government policies and regulatory frameworks are crucial in shaping the future of sustainable transportation. Incentivizing the adoption of electric vehicles, supporting the development of sustainable fuels, and establishing clear standards for emissions reduction are all essential components of a comprehensive strategy. These policies act as catalysts, creating a supportive environment for innovation and investment in sustainable transportation solutions, ultimately paving the way for a cleaner and more efficient future for all.

Economic Impacts and Job Creation: A Sustainable Future

The shift to sustainable transportation is creating significant economic opportunities. The development and production of electric vehicles, sustainable fuels, and charging infrastructure are generating new jobs in various sectors. This transition also leads to reduced reliance on fossil fuels, which has positive implications for energy security and global trade relations. Furthermore, this growth creates a ripple effect, fostering innovation and collaboration across industries and driving economic development in a sustainable and responsible manner, ultimately benefitting society as a whole.